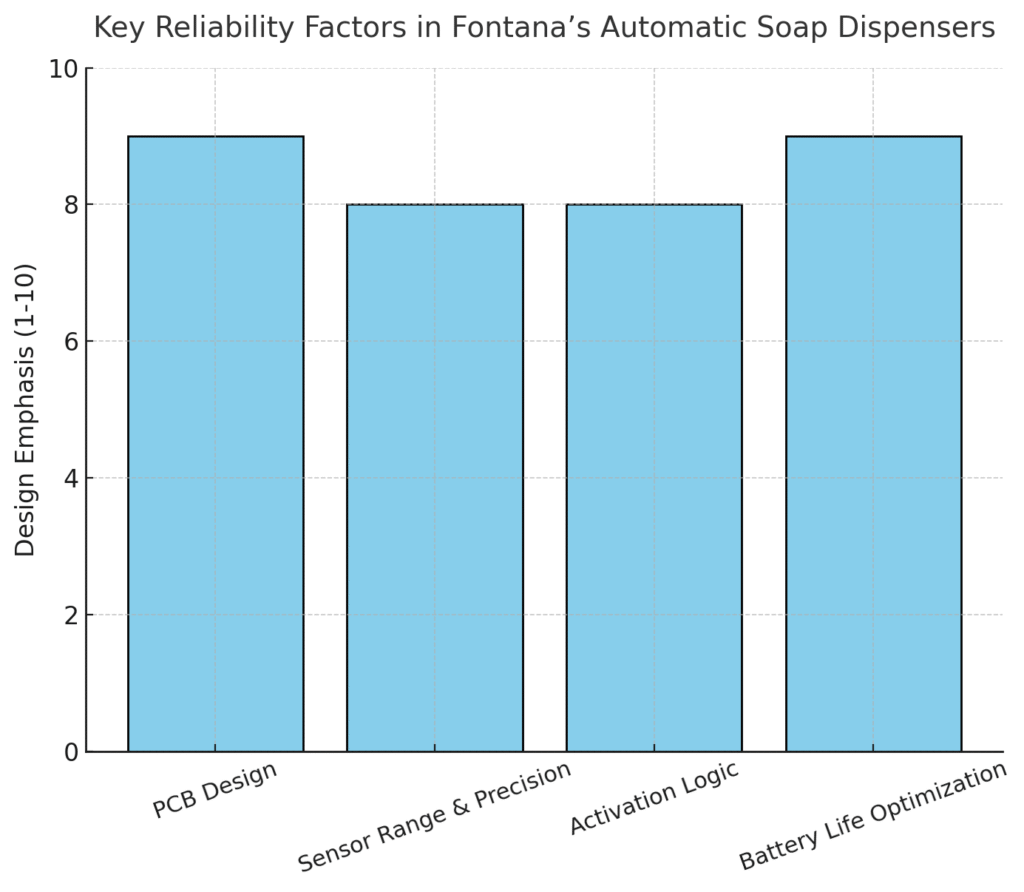

Reliability • Electronics • Sensors • Power Optimization

Modern bathrooms have gotten the user experience down to a science. Touchless soap dispensers are not a luxury any more—hamburgers are the standard. Smoothness, consistency, and reliability are the criteria upon which a bathroom leaves a lasting impression or fails to impress. Fontana’s manufacturing of dependable automatic soap dispensers is all about tighter oversight of the electronics: the printed circuit boards (PCBs), sensor technologies, activation logic, and power optimization technologies that enable each device to work without a glitch day after day.

In this article, we’ll step inside the electronic heart of Fontana’s dispensers and explore how thoughtful engineering delivers reliability that facility managers can count on.

The PCB’s Role in Durability

Under every automatic soap dispenser lies its printed circuit board (PCB). Tiny control hub that it is, it controls all the action required—from interpreting sensor signals to driving motor-driven pumps. Fontana’s PCB design for ruggedness and modularity:

- Component Placement for Reliability

Weak components, i.e., microcontrollers and infrared sensor receivers, are stored away from heat sources and exposure to moisture. Splash protection against soap, environmental stress in the form of nature in commercial toilets, and humidity protection use waterproof coatings (conformal coatings). - Signal Integrity

The circuit design is such that it produces minimum electric noise and hence the sensor system will work properly even if dispensers are arranged side by side. It possesses spurious triggering avoidance and no volume change in dispensing. - Fail-Safe Pathways

Redundant operation exists and hence even in path failure the dispenser works properly.

With enhanced PCB design, Fontana toughens up the minds of the dispenser to survive day-in-and-day-out beating of high-traffic installations.

Sensor Range and Accuracy

A telltale sign of a good dispenser is consistent activation—dispensing soap when individuals require it and not otherwise. Fontana does it with just enough carefully calibrated infrared (IR) sensors:

- Optimized Range

Sense zone is 2–4 inches from the nozzle, empirically determined value in the field. It prevents users from accidental waving and spurious triggering on movement in the region. - Environmental Calibration

Bathroom environments pose issues of reflectivity surfaces, lighting rate of change, and varied user flow patterns. Fontana’s electronics also employs adaptive calibration logic, e.g., ambient light and reflectivity interference to regulate sensitivity. - Consistency Over Time

Sensor degradation is something accommodated by economy dispensers. Fontana attains sensor reliability at thousands of cycles with use of high-quality photodiodes and signal amplifier circuitry.

This very broad sensing range allows for smooth, reliable user operation, the cause of complete customer satisfaction.

Activation Logic: Smart Dispensing Control

At the center of user experience lies the logic by which the dispenser determines to dispense and to what volume. Fontana’s activation logic goes beyond hardware and software:

- Debounce Algorithms

Electronics debounce spurious activation from quick hand movement or background noise. It prevents wasteful soap dispensing. - Fixed Dispense Volumes

Logic circuits regulate pump time in such a way that every cycle of use is releasing the same and metered amount. This maximizes soap usage as well as bathroom cleanliness via prevention of drips. - Adaptive Delay Mechanisms

In order to prevent abuse in high-use facilities, the system delays against multiple quick release by a single user. This avoids efficiency vs. conservation through prevention of sequential usage by a single user.

Cumulatively, these levels of logic illuminate the dispenser, making it more energy efficient and responsive to commercial usage requirements.

Optimized Battery Life

Of all the drivers of dispenser reliability, perhaps the least recognized is power management. In the office, wasteful battery replacement means wasted maintenance dollars and lost hours. Fontana engineers have attacked power management with a fanatic mindset:

- Low-Power Microcontrollers

At the heart of the circuitry are ultra-low-power microamps-sipping processors. - Efficient Power Paths

Power is provided to operational equipment in use, with fewer leads in idle state. - Pulse-Width Modulation (PWM) Control

PWM enhances motor efficiency, providing an amount of power required for working soap flow with wasteful overuse avoided. - Battery Compatibility

The dispensers are effectively designed through the use of rechargeable and alkaline types of batteries, advancing facilities simplicity towards sustainability standards.

The net gain is months of battery life—essentially even on high-usage bathrooms—and lower maintenance cycles and overall cost savings.

Fontana Automatic Soap Dispenser – Reliability Factors

| Category | Key Features | Reliability Impact |

|---|---|---|

| PCB Design | Solid construction, water-resistant coatings, signal integrity, fail-safe tracks | Avoids long-term failure and durability in wet environments |

| Sensor Range & Precision | 2–4 inch range, adaptive calibration, high-quality sensors | Delivers correct user experience without ghost alarms |

| Activation Logic | Debounce algorithms, even dispensing amounts, adaptive hold techniques | Saves waste, uniform, and optimises efficiency |

| Battery Life Optimization | Power-saving microcontrollers, PWM motor control, low-power standby, extended battery life | Optimises maintenance cycles and minimises running cost |

Why Reliability Matters

Reliability is all technical reliability, because it’s in business operators’ and building owners’ best interests. Operating reliability is where it’s most critical. When a dispenser breaks down, it shuts down user flow, generates maintenance calls, and ruins facility trust. Fontana attention to detail in circuitry design—from PCB lifespan to sensor accuracy and power savings—gets operators in fewer headaches and guests in a better experience.

It is the age of cleanliness high-stakes, and mistake is not allowed. A good dispenser is not a luxury—a flat necessity.

Conclusion

Reliability is Fontana’s engineering tradition—a guarantee. With an unshakeable focus on putting solid PCB design first, accurate sensor calibration, intelligent activation logic, and state-of-the-art battery optimization, Fontana automatic soap dispensers are commercial gold standard for performance.

To designers, architects, and facility managers looking for rest room equipment where style is matched with functionality and technology, Fontana provides equipment that will last the test of time. Reliability is not an accident—it’s built into every circuit.

Source links and references

Location: New York, NY

Profile: Commercial restroom design expert. Works with architects and facility managers to integrate touchless aviation faucets into airports, office towers, and mixed-use developments with ADA and code compliance.