ToF Sensing • Durability • Code Coordination • System Integration

Technical summary for architects and engineers specifying commercial and institutional washrooms.

Scope and Use Context

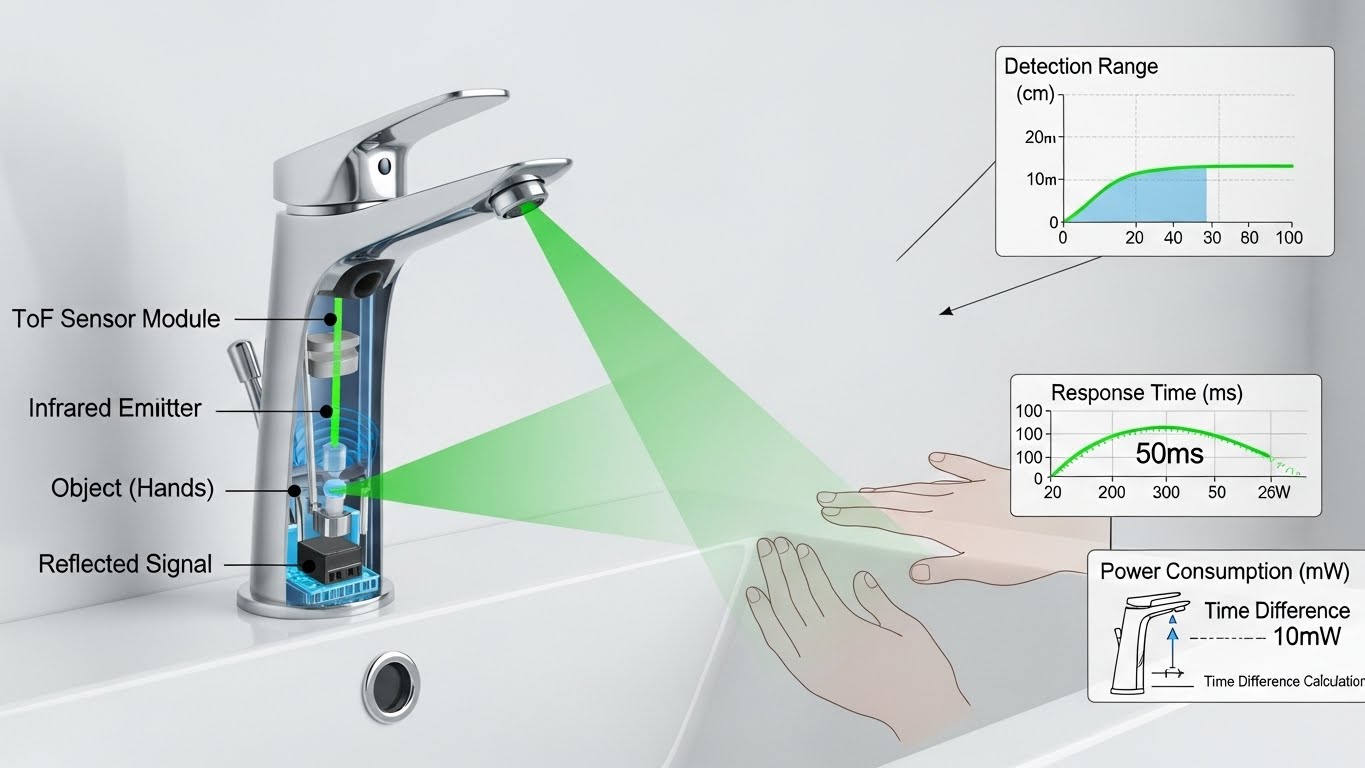

ToF sensing provides distance-based activation of solenoid valves in touchless faucets across airports, healthcare, higher-education, and civic facilities. Unlike intensity-based IR, ToF measures the round-trip time of modulated near-infrared light to compute absolute distance, improving stability under variable lighting, reflective basins, and compact geometries.

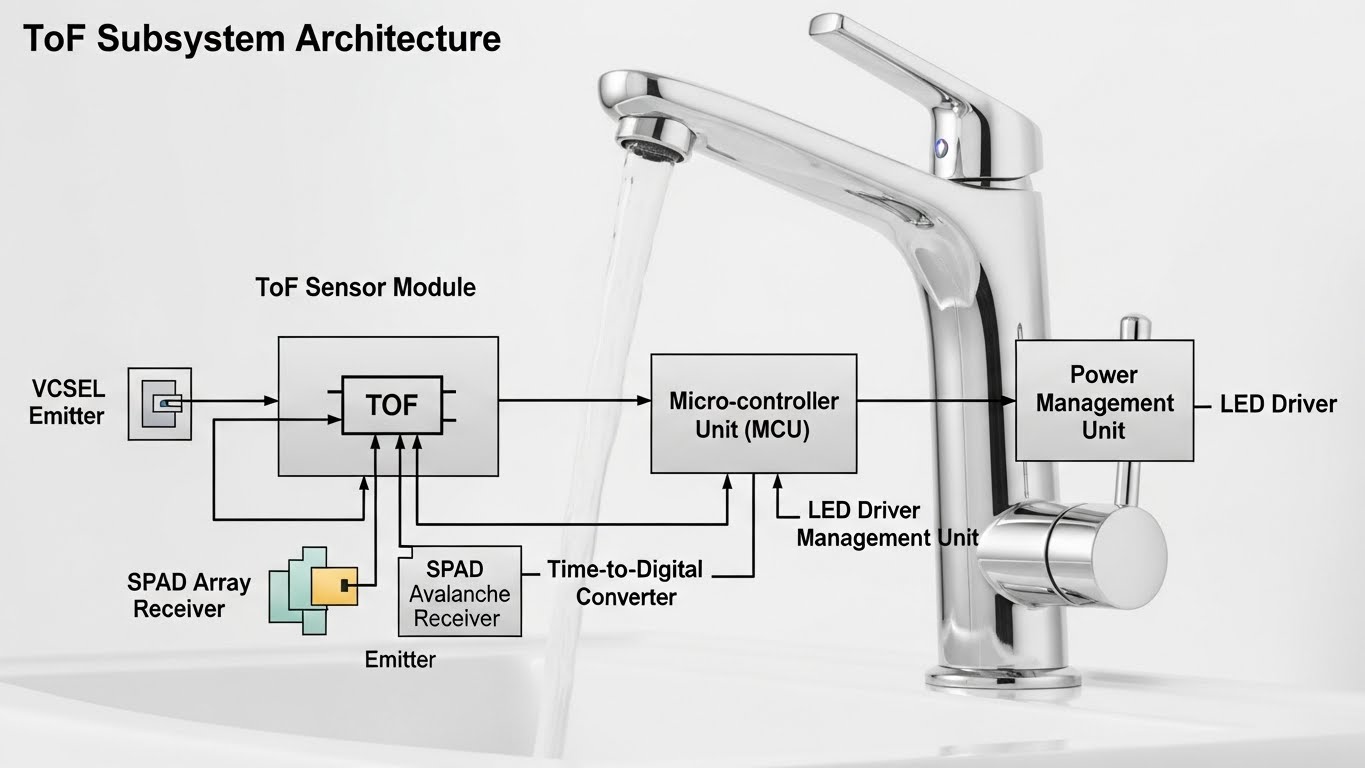

Operating Principle

ToF emitters project modulated NIR (≈850–940 nm). The receiver measures phase shift or direct flight time of the reflected signal; thresholds and hysteresis are processed by an MCU which drives a latching or non-latching solenoid with timeout and debounce logic.

| Subsystem | Engineering Notes |

|---|---|

| Emitter/Receiver | Modulated NIR illumination; photodiode/CMOS array for range computation; optical aperture sealed behind hydrophobic window. |

| ToF SoC / MCU | On-device signal processing (background cancellation, temporal filtering), adaptive calibration, watchdog and brownout protection. |

| Valve Driver | Low RDS(on) FET bridge for latching solenoids; flyback or TVS suppression per EMC plan. |

| Power | Battery (e.g., 6 V) and/or low-voltage DC; optional AC adapter. Duty-cycle control minimizes average current draw. |

| Enclosure | Ingress-protected (e.g., IP65–IP67) sensor cavity; gasketed connectors; ESD shielding and vandal resistance as required. |

Background on ToF system design: TI application notes and ST multi-zone ToF modules offer component-level guidance suitable for compact faucet integrations.

Performance Characteristics (Typical Targets)

Detection

- Absolute distance measurement resists specular false triggers from rims and garments.

- Configurable activation window & hysteresis; optional multi-zone ranging for spatial filtering.

Power & Controls

- Pulsed emission with duty-cycled processing for battery or LVDC operation.

- Programmable run-time limits, lockouts, purge/thermal disinfection modes for facility operations.

Durability

- Ingress protection specified to location (e.g., IP65–IP67) and cleaning regime.

- Corrosion-resistant alloys/finishes; strain-relieved harnessing; front-serviceable modules.

Hygiene & Sustainability

- Hands-free operation supports infection-control goals.

- Flow/time tuning to meet project efficiency targets aligned with WaterSense/CALGreen where adopted.

Accessibility, Efficiency, and Code Coordination

ADA

Confirm clear floor space, reach ranges, and operable-parts usability per ADA 2010 for accessible lavatories. Sensor-operated controls shall not require tight grasping, pinching, or twisting.

WaterSense

Specify faucet flow rates and performance certified under EPA WaterSense where the program is used to support conservation or utility rebates.

CALGreen

For California projects, coordinate maximum flow and automatic control requirements under CALGreen and local amendments.

ASME A112.18.1/CSA B125.1

Touchless lavatory fittings and accessories between stops and terminals fall within ASME A112.18.1/CSA B125.1 scope. This is for mechanical integrity, hydraulic performance, endurance, and marking.

System Integration & Commissioning

Hydraulics & Mixing

- Thermostatic/mixing valves sized to fixture-unit loads; validate pressure/flow for simultaneous use.

- Scald protection and backflow per plumbing code and facility standards.

Electrical & Controls

- Battery or LVDC with isolation; surge and EMC mitigation matched to site conditions.

- Commissioning: activation range, run-time, cleaning lockouts, purge/flush policies.

BIM & Documentation

- Provide geometry, clearances, connections, and MEP parameters in BIM models per NBIMS-US.

- O&M: strainer cleaning intervals, battery schedule, sensor window maintenance.

Environmental Protection

- IP rating appropriate to splash zone and cleaning chemicals; sealed connectors.

- Material/finish selection for corrosion resistance and life-cycle serviceability.

Brand Implementations & Spec Resources (Selected)

FontanaShowers® — Touchless & Aviation

- Touchless Faucet Category: fontanashowers.com/Touchless-Sensor-Faucets-s/1901.htm

- Touchless Faucet + Soap Dispenser Set (FS1816): fontanashowers.com/p/fs1816.htm

- Aircraft Lavatory Touchless Faucets (program pages): fontanashowers.com/s/8502.htm

Sloan® — Optima/BASYS & EPDs

- Faucets (overview): sloan.com/products/faucets

- Optima® EBF Series — Environmental Product Declaration (technical LCA): en.sloan.com/…/Sloan Optima EBF EPD.pdf

- Product detail (example): sloan.com/products/faucets/standard/sf-2250

TOTO® — Touchless Technical Sheets

- Touchless Wall-Mounted Faucet (spec page): in.toto.com/product/touchless-faucet-wall-mounted-3/

- Spec PDFs (examples): TLE27002A · TLE26010A

BathSelect® — Commercial/Hospitality

- Hospitality (commercial program hub): bathselecthospitality.com

Sustainability Considerations

- Water & Energy: Configure flow/time for WaterSense-aligned performance (where adopted) to reduce fixture water and hot-water loads.

- Maintenance: Front-serviceable cartridges/solenoids, standardized strainers and seals, documented preventive maintenance.

- Materials: Low-lead alloys and compliant elastomers; verify NSF/ANSI 61 where required by project type.

- Documentation: Where available, use manufacturer EPDs to inform project LCA analysis and sustainability narratives.