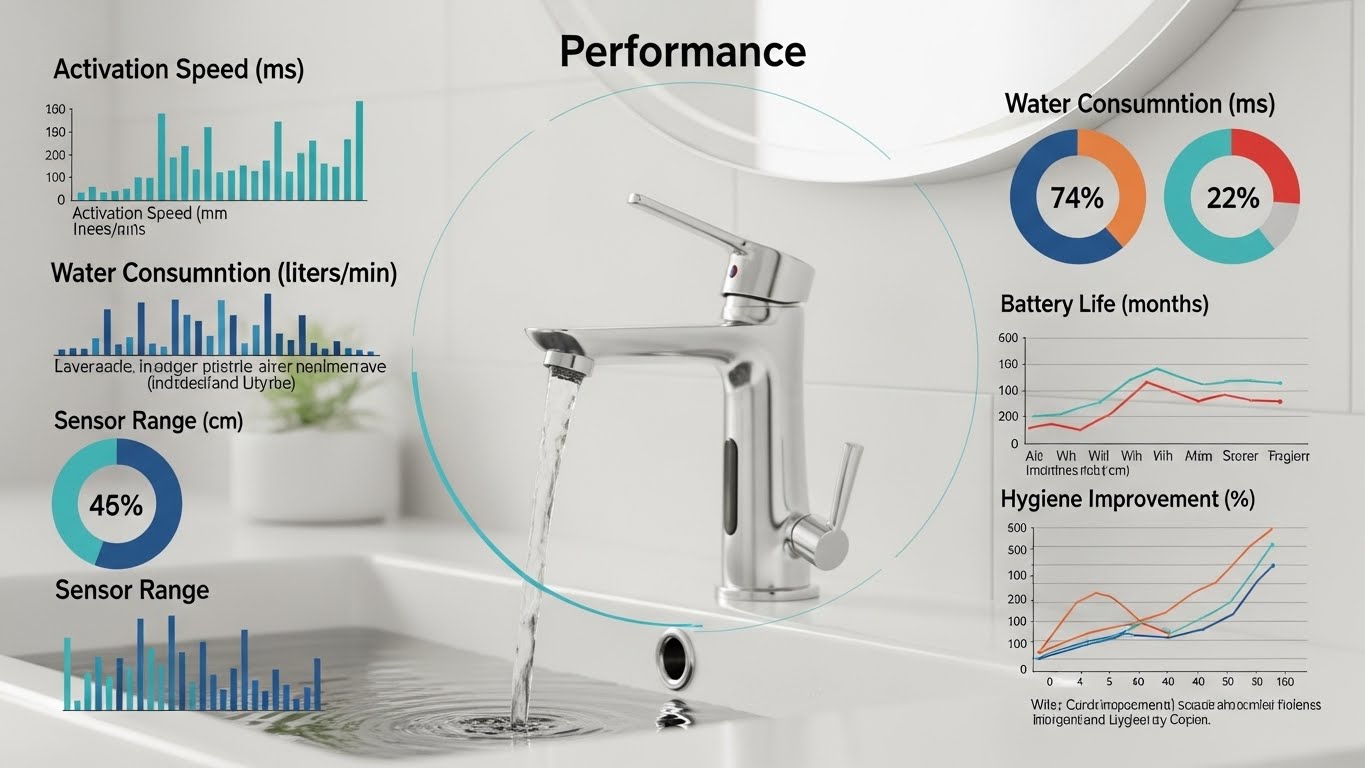

Performance Data • Codes & Standards • Water Efficiency • Maintainability

In commercial and institutional projects today, touchless faucets are not a specialty item but rather a base expectation for hygiene, water efficiency, and accessibility. For architects, engineers, and specifiers, the design decision is no longer “manual vs. sensor” but how to evaluate and document performance characteristics so the installed product will comply with codes, integrate with building systems, and remain maintainable over the life of the facility.

Three parameters usually drive most of the engineering discussion:

- Flow rate (gpm or L/min)

- Sensor range and detection logic

- Power efficiency and power strategy

These parameters conform to consensus codes and standards for plumbing supply fittings, ASME A112.18.1/CSA B125.1, EPA WaterSense® specifications, CALGreen water-efficiency requirements, and ADA accessibility criteria.

The following sections describe how to interpret these data for use in commercial specifications.

Regulatory and Standards Framework

ASME A112.18.1/CSA B125.1 – Performance and Test Methods

The core performance standard referenced by energy and water codes for faucet testing is ASME A112.18.1/CSA B125.1. It includes test procedures for flow rate, endurance, leakage, and mechanical performance of plumbing supply fittings, including electronic (sensor) faucets.

A/E teams should check the following whenever reviewing cut sheets:

- The faucet is listed to ASME A112.18.1/CSA B125.1

- Flow performance and pressure data are stated explicitly at standard pressures, normally 60 psi for maximum flow

This standard is directly referenced by many federal and state-level regulations, such as DOE test procedures and various green codes.

WaterSense and CALGreen – Flow Rate Limits

Although written originally for private lavatory faucets, the WaterSense threshold sometimes informs owner standards and green building policies in non-residential applications. It sets a maximum flow rate of 1.5 gpm at 60 psi, at least 30% below the U.S. federal baseline of 2.2 gpm.

By contrast, CALGreen and local water-efficiency ordinances often specify flow rates that are significantly lower for public and common-use lavatories. One recent CALGreen provision has specified that lavatory faucets in common and public-use areas for many occupancy categories be limited to 0.5 gpm at 60 psi. Similar limits are widely adopted for non-residential public lavatories.

For specifiers, this generally means:

- Private or staff restrooms may be governed by WaterSense or similar internal standards (≤1.5 gpm)

- Public or high-traffic restrooms may require ≤0.5 gpm dictated by codes equivalent to CALGreen or by local amendments

Touchless faucets normally use laminar or aerated devices and internal flow regulators to meet these thresholds.

ADA – Operable Parts and Reach Ranges

Although ADA does not regulate flow rate, it does drive geometry and user interaction. The ADA Standards require operable parts, including faucet sensors, manual override controls, and temperature adjustment, to be within allowable reach ranges and operable without tight grasping, pinching, or twisting of the wrist.

Key implications:

- The effective sensor activation zone shall be located within the forward or side reach of the user, no more than 48 inches from the floor, lowered to 44 inches if over deep counters.

- Manual mixing controls or override buttons shall be operable from the wheelchair knee/toe clearance envelope in sinks, as required by ADA.

Flow Rate: Data, Design, and System Impacts

Understanding Flow Metrics

Performance data for flow should at least include:

- Maximum flow rate (gpm or L/min) at 60 psi

- Minimum operating pressure to retain a steady, usable stream

- Type of flow – laminar vs. aerated – and outlet device

- Metering behaviour – if the faucet uses timed run cycles

For touchless operating commercial lavatory faucets, 0.35–0.5 gpm at 60 psi has become common for high-performance designs seeking compliance with green building criteria.

Reduced flow, from an engineering perspective, affects:

- The other factors that can affect hot water sizing, recirculation loop design, and temperature maintenance strategies include lower diversified demands.

- Drainage system – very low flows can lower the self-scouring in long horizontal runs, which must be considered with the fixture group layout

- User perception – even at 0.35–0.5 gpm, delivery must be stable and splash-free, especially in shallow basins

Test Conditions and Tolerances

Most of the codes and green standards refer to flow measured at 60 psi using the ASME test protocol.

For specification,

- Require manufacturers to declare rated flow at 60 psi, tested per ASME A112.18.1/CSA B125.1

- Specify if pressure-compensating flow control is used, and, if the building typically operates at higher or lower pressures, request performance curves across an applicable pressure range (such as 20–80 psi)

- For electronically activated faucets of the metering style, confirm flow rate and run time per activation cycle so that total volume per use can be estimated.

Integrating Flow Performance into Water Budgets

When preparing the CALGreen or equivalent water-use worksheets, the A/E team may be required to demonstrate percentage reductions in indoor water use from a baseline.

For every lavatory group:

- Use the specified flow rate, such as 0.5 gpm, and assumed average run time per use. Many sensor faucets average 10–12 seconds per use

- Combine with projected fixture usage per occupant to derive annual water consumption.

- Compare against baseline assumptions (e.g., 2.2 gpm manual faucets) to quantify savings

Touchless operation has the potential to further reduce consumption by controlling run time, but this is a behavioral factor and usually not directly credited in code calculations.

Sensor Range and Detection Performance

Defining Sensor Range

In general, sensor range in electronic faucets describes the distance from the sensor at which a user’s hands are detected and water flow is triggered. This may be specified as:

- A single nominal activation distance—e.g., about 75–150 mm from the sensor window, or

- A detection “zone” defined in terms of the basin geometry

From a design perspective, the sensor shall:

- Detect hands within the natural arc of use at the lavatory

- Avoid false triggers from reflections, adjacent users or moving objects

- Perform well for a range of ambient light and surface conditions, including polished versus matte basins.

Interaction with Basin Geometry

Sensor range should be coordinated with:

- Spout reach and height relative to waste

- Bowl depth and slope

- Counter overhang and ADA knee/toe clearances

A sensor distance that is too great can result in activation when a user simply approaches the lavatory and wastes water. Sensors set to too short of a range force users to “hunt” for the sensor, an ADA usability concern.

For complex configurations of vanity, it is often useful to:

- Request sensor range diagrams from manufacturers

- Perform mock-ups in test lab and/or on-site to validate performance for selected basins and countertop finishes

ADA and Human Factors

This ADA requirement of operable parts being within accessible reach ranges means that the practical sensor activation zone also has to fall inside that envelope, even when the sensor itself may be hidden.

Specifiers should check:

- The front edge of the counter and faucet positioning do not require a reach exceeding 48 inches (or 44 inches when reaching over deep counters)

- Any override or temperature control that is manual can be operated with one hand and without tight grasping, or twisting

- Minimize visual clutter with detailing where possible, but clearly provide the user with cues regarding placement of their hands.

Power Efficiency and Power Strategy

Power Options

Commercial touchless faucets are commonly powered by one or more of the following:

- Battery-only: e.g., AA/9V packs

- Hard-wired low-voltage from a transformer or power supply

- Hybrid (battery + plug-in, w/ automatic failover)

- Energy-harvesting systems with small turbines in the supply line

Power efficiency within the sensor and solenoid assembly has direct impacts on battery life, transformer sizing, and long-term maintenance.

Reading Power Performance Data

Key metrics to request and analyze:

- Standby current draw (μA or mA)

- Current during activation in mA and duration of activation

- Rated battery life in years and number of activations under the following specified conditions: example – 300 uses/day at 60 psi, 0.5 gpm, 12 s run time, 72°F ambient

- Voltage range in which the electronics will operate reliably

With battery-only solutions, high-traffic restrooms, like those in transportation hubs and stadiums, will need frequent service unless the installation includes energy-harvesting technology. Hardwiring low-voltage installations reduces service calls but introduces coordination requirements with electrical design.

Integration with Building Systems

In more sophisticated installations, touchless faucets could be part of a building management system or dedicated plumbing management platform and include features such as:

- Fault warning: valve failure, low battery, sensor malfunction

- Usage data: counts of activations, peak-hour loads

- Remote configuration: run times, sensor sensitivity, cleaning modes

From a specification perspective, it is important to:

- Explanation of communication protocols: BACnet/IP, Modbus, proprietary gateways

- Identify any IT and cybersecurity requirements if the devices are on the facility network

- Coordinate power and data pathways with the MEP disciplines to avoid retrofits

Durability, Sustainability, and Lifecycle Considerations

Durability and Abuse Resistance

Since failure in institutional settings is less driven by electronics and more driven by:

- Mechanical abuse: impact, vandalism

- Chemical exposure from aggressive cleaning agents

- Water quality: scale, sediment, corrosive conditions

Where possible, require evidence of:

- Cyclic testing (e.g. number of on/off cycles) to ASME or manufacturer’s internal protocol

- Ingress protection ratings for sensor windows and electronic modules

- Covers and solenoid enclosures designed to resist tampering

Sustainability beyond flow rate

Sustainability is not just about flow reduction.

- Material selection: low-lead brass, stainless, or high-performance polymers; can be potentially recyclable

- Serviceability: Replaceable cartridges, solenoids, and electronics reduce whole unit replacement and waste.

- Energy efficiency: Lower power draw extends battery life and reduces battery waste; where hard-wired, it reduces parasitic electrical load.

These factors can be included in either owner project requirements, or sustainability criteria beyond code minimums.

Specification Checklist for Architects and Engineers

When preparing Division 22 specifications and reviewing submittals for commercial touchless faucets, consider requesting at least the following information:

Flow Performance

- Rated maximum flow (gpm at 60 psi), tested in accordance with ASME A112.18.1/CSA B125.1

- Confirmation of compliance with applicable WaterSense, CALGreen, or local flow limits based on the project location

- Flow-pressure curve and minimum operating pressure

Sensor and Usability

Sensor activation range and detection zone diagrams

Typical response time (time from detection to full flow)

Confirmation that the sensor activation zone and the manual controls can be installed within required ADA reach ranges for the specified lavatory configuration

Power and Controls

Type of power: battery, low voltage, hybrid; rated battery life (activations and years) under defined usage.

Standby and active current draw

Network/BMS integration options and required infrastructure where applicable

Durability and Maintenance

Listing to ASME A112.18.1/CSA B125.1 and other relevant certifications

Documentation of cycle testing and environmental testing: temperature, humidity, cleaning chemicals

Parts availability and recommended maintenance intervals

By tying performance data to generally recognized standards, such as WaterSense, CALGreen, ASME, and ADA, design teams can justify product selection, support code compliance, and give owners a clear understanding of what lifecycle performance can be expected. The result is not just a “touchless” restroom, but rather a coordinated, efficient, and maintainable water-delivery system aligned with long-term goals for operation and sustainability.

Location: New York, NY

Profile: Commercial restroom design expert. Works with architects and facility managers to integrate touchless aviation faucets into airports, office towers, and mixed-use developments with ADA and code compliance.