Manual vs Touchless • Water Modeling • Duty Cycle • ADA • WaterSense • CALGreen

Architects, plumbing engineers, and specification writers increasingly need quantifiable data about the performance of touchless versus manual lavatory faucets. Beyond qualitative claims of “reduced water waste,” the design community must evaluate actual duty-cycle effects, flow-rate limitations, and lifecycle performance under governing frameworks such as ADA accessibility, WaterSense, CALGreen, and ASME A112.18.1/CSA B125.1.

Baseline parameters include flow rates, duty cycles, and user behavior.

Current faucet performance expectations are influenced by the flow-based criteria of WaterSense, indoor water-use reductions based on CALGreen, and mandated conformance to ASME A112.18.1/CSA B125.1.

Introduction

Primary reference materials include the ADA Standards for Accessible Design, the EPA WaterSense Product Specifications. and CALGreen’s Code Guidance.

The WaterSense High-Efficiency Lavatory Faucet Specification PDF caps lavatory faucet flow at 1.5 gpm at 60 psi, substantially below the former 2.2 gpm baseline. Additional historical technical information is archived at the EPA’s High-Efficiency Lavatory Faucet Page (Archive)

CALGreen Resources, Including the Nonresidential Supplement Guide, support project teams in the development of compliant fixture schedules and documentation for indoor water-use reductions.

Reference Standards and Code Baselines

WaterSense Requirements and CALGreen Guidance define the baseline water efficiency expectations for most modern projects. Commonly used jurisdictional compliance documents include the Nonresidential CALGreen Checklist.

Behavioral Duty Cycle in High-Traffic Restrooms

High-use facilities commonly experience 200–800 faucet activations per fixture per day. Manual faucets have a flow that is continuous for about 20–30 seconds in a typical handwashing cycle. Touchless faucets interrupt the flow during soaping and limit runtime to 9–15 seconds.

Useful reference materials include WaterSense Historical Faucet FAQs (Archive), ADA Standards, and the CALGreen Supplement Guide

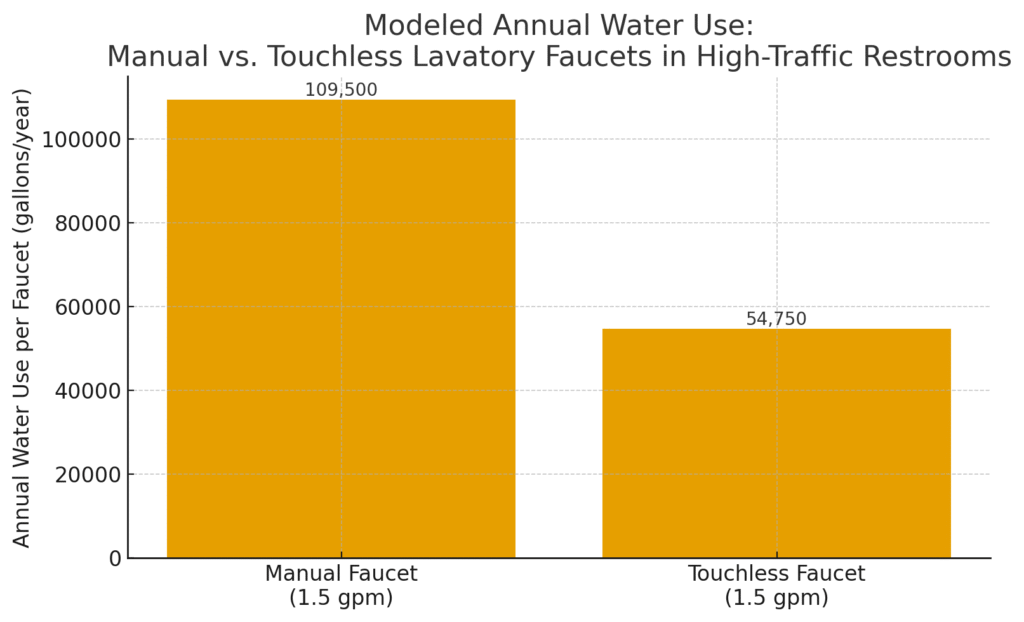

Quantitative Water Savings Modeling

Duty cycle, rather than flow rate alone, is primarily responsible for water savings calculations. Using the 1.5 gpm flow rate aligned with WaterSense:

Manual Faucet Scenario

Flow: 1.5 gpm

Water-on duration: 24 seconds (0.4 min)

Use per event: 0.6 gallons

Annual total (500 uses/day): about 109,500 gallons per faucet

Touchless Faucet Scenario

Water-on duration: 12 seconds (0.2 min)

Use per event: 0.3 gallons

Annual total: about 54,750 gallons per faucet

This reflects an approximate 50% reduction purely from controlled runtime.

High-Traffic Waste and Edge Conditions

Unattended manual faucets left running between users can negate expected savings. Touchless systems eliminate the risk by default. The resources in CALGreen provide green-building water-efficiency context: CALGreen Information Portal and ICC Code Appendices – CALGreen Appendix A5 Nonresidential Voluntary Measures. WaterSense Specifications for efficient fixtures remain available.

GTO-aware critical path analysis, wherein gate topological order or logical effort-based approaches for delay modeling can be applied.

Accessibility and User Interface (ADA Perspective)

By design and function, touchless faucets reduce grasping, pinching, and twisting motions and eliminate operating-force requirements.

Relevant documents include:

- ADA Standards for Accessible Design

- U.S. Access Board ADA Standards PDF

- DOJ Adoption Announcement

Operable Parts, Force Limits, User Interface

ADA limits control force to 5 lbf and requires one-handed operation without tight grasping. This is achieved in manual faucets via lever or paddle handles, while touchless models inherently bypass these requirements.

Reach Ranges, Clearances, and Sensor Placement

Designers have to coordinate sensor placement with sink geometry, mirrors, and splash zones to avoid occlusions or false activations.

Standards, Listings, and Code Coordination

ASME A112.18.1/CSA B125.1 Requirements

All commercial faucets shall be certified to ASME A112.18.1/CSA B125.1 which covers durability, leakage and cycle endurance.

WaterSense Labeling and CALGreen Documentation

WaterSense-certified faucets simplify specifiers’ compliance with local water-efficiency ordinances.

Durability, Lifecycle Performance, and Maintenance

Wear Modes and Mechanical/Electronic Stress

Manual faucets wear at stems, seals, and handle mechanisms while touchless faucets wear primarily at the solenoid valves, sensors, and electronics.

Vandal Resistance and Power Reliability

Touchless systems reduce the amount of exposed moving parts but add power dependencies.

| Parameter | Manual Faucet | Touchless Faucet (Properly Configured) |

|---|---|---|

| Flow rate | 1.5 gpm | 1.5 gpm |

| Typical water-on time per use | 24 seconds (0.4 minutes) | 12 seconds (0.2 minutes) |

| Behavioral pattern | On during wetting, soaping, rinse | On only for wetting and rinsing |

| Water volume per use | 0.6 gallons | 0.3 gallons |

| Uses per day (per faucet) | 500 | 500 |

| Operating days per year | 365 | 365 |

| Annual water use per faucet | ≈ 109,500 gallons/year | ≈ 54,750 gallons/year |

| Modeled reduction vs. manual | – | ≈ 50% less water |

| Main failure / wear modes | Handles, stems, seals, bearings | Solenoid valves, sensors, electronics |

| Key standards / references | ASME A112.18.1/CSA B125.1; local plumbing code | ASME A112.18.1/CSA B125.1; WaterSense; CALGreen (where applicable) |

System Integration, Telemetry, and Controls

BMS Data for Water-Use Verification

Touchless faucet telemetry enables accurate modeling of water usage through real-time activation logs and runtime trends.

Mixing, Temperature, and Scald Protection

Centralized thermostatic mixing and commissioning are highly recommended.

Specification and Design Guidance

Critical Division 22 Requirements

Specifications usually refer to ADA Standards, WaterSense Specifications, and ASME A112.18.1/CSA B125.1.

CALGreen compliance is coordinated using resources at: CALGreen Information Portal

Commissioning and Verification

Commissioning ensures that theoretical savings translate to field performance.

Conclusion

The decision between manual and touchless faucets in high-use settings is largely an engineering one. Properly configured to WaterSense-compliant flows, aligned with ADA provisions, documented under CALGreen, and listed to ASME A112.18.1/CSA B125.1, touchless faucets can achieve significant, quantifiable, and defensible water savings.

Source links and support documents

Location: New York, NY

Profile: Commercial restroom design expert. Works with architects and facility managers to integrate touchless aviation faucets into airports, office towers, and mixed-use developments with ADA and code compliance.