Durability • Reliability • Code Alignment • Public Restrooms

In high-traffic public and institutional facilities, touchless faucets are not “nice-to-have” fixtures but highly critical infrastructure. Indeed, airports, schools, hospitals, and transit hubs can see thousands of actuations per faucet per day. In these environments, failures aren’t just inconvenient but impact hygiene, water conservation goals, ADA accessibility, and compliance with local green building codes such as CALGreen.

That is why architects and engineers today increasingly rely on structured, repeatable durability and reliability testing when evaluating touchless faucets for specification. In such tests, the objective is to assure a given product will sustain performance over its expected service life under realistic operating conditions, rather than in ideal lab conditions only.

Test Program Overview

Objectives and Scope

A proper test program for off-the-shelf touchless faucets in public facilities might have four fundamental aims:

Mechanical Durability- The resistance of wear on moving parts such as the solenoid, seals, aerators, and mounting hardware to hundreds of thousands of cycles.

Hydraulic Stability: Consistency of flow rate, quality of shutoff, and resistance to debris and pressure fluctuation.

Reliability of controls and sensors: stable detection against various users, light, and water conditions; also, “fail-safe” behavior.

Regulatory and Sustainability Alignment: Demonstrated compliance with ASME, ADA, WaterSense, CALGreen, and applicable plumbing codes.

The test population will be a mix of battery-powered versus hardwired configurations, deck-mounted versus wall-mounted variants, and flow-rate configurations ranging from standard efficient to ultra-low-flow for CALGreen or other local requirements.

Standards and Codes Referenced

While more detailed tests may be project or manufacturer-specific, they are usually in line with: ASME A112.18.1/CSA B125.1 – Plumbing supply fittings: This standard specifies performance and life-cycle tests for fittings between the supply stop and the terminal opening. WaterSense® specifications for lavatory faucets typically cite maximum flows at or below 1.5 gpm at 60 psi with referenced test methods ASME A112.18.1.

CALGreen plumbing fixture requirements, which cap public/common-area lavatory faucets in many California projects at 0.5 gpm at 60 psi.

ADA scoping and technical requirements for operable parts require that faucet controls (and any manual overrides or mixing devices) be usable with one hand, without tight grasping, pinching, or twisting of the wrist, and with no more than 5 lbf of operating force.

These references constitute the backbone of test protocols employed in the evaluation of durability and reliability.

Mechanical Durability and Resistance against Vandalism

Life-Cycle Actuation Testing

For public facilities, the life-cycle testing is typically run on the order of hundreds of thousands of actuations, representing several years of high-traffic usage. One representative protocol might be:

Cycle the faucet on a defined duty cycle such as 5–10 seconds on, 15–20 seconds off.

Run over a range of inlet pressures, typically between 20–80 psi.

Periodically check flow rate, shutoff time, and leakage.

Key observations that come out of such test programs are generally:

The robustness of the solenoid valve is the prime determinant of long-term reliability. Designs incorporating stainless or corrosion-resistant components, and also with good filtration upstream, maintain consistent response and minimal leakage after life-cycle testing.

Seals and O-ring performance under repeated expansion/contraction and sometimes pressure spikes can drive maintenance frequency. Higher-quality elastomers and correct compression profiles have significantly reduced failures.

Mounting integrity: deck or wall must be able to resist rotational and lateral loads. In public restrooms, there are often unintended forces applied to the spout; better designs incorporate anti-rotation pins, backing plates or reinforcement brackets.

Environmental and Ingress Protection

Public restrooms are a harsh micro-environment: high humidity, cleaning chemicals, and frequent thermal swings. For touchless faucets, protection of electronics is critical:

Ingress protection for both sensor modules and control boxes is tested by means of water spray and, if necessary, temporary submersion.

Tests for resistance to cleaning agents and disinfectants include those for conformal coatings, sealed housings, and gaskets.

Vibration and pull tests validate wiring harness strain relief and connector robustness.

The results of such tests determine if a faucet is suitable for use indoors only, in semi-conditioned public spaces, or in more demanding conditions such as transportation hubs with open-air concourses.

Hydraulic Performance, Water Efficiency, and Code Alignment

Flow Rate Stability and Efficiency

Hydraulic testing focuses on delivering:

A stable laminar or aerated stream that is within design flow limits over the usual range of municipal pressures.

Comply with WaterSense and CALGreen when applicable, especially when owners strive to achieve a LEED, IgCC, or state-level green code alignment.

Testing typically includes:

Flow at 20, 60, and 80 psi, checking to ensure faucet does not surpass maximum flow limits such as ≤ 1.5 gpm for WaterSense-labeled lavatory faucets or ≤ 0.5 gpm for some CALGreen public lav applications.

Flow verification before and after life-cycle testing per ASME A112.18.1 procedures to confirm that unacceptable deviations do not result from erosion, debris, or wear.

From a specification viewpoint, the following needs to be called out:

The design flow rate, with reference to the applicable standard and test method, such as “tested in accordance with ASME A112.18.1/CSA B125.1”.

Whether the faucet is WaterSense-labeled, often relevant for private or tenant spaces; whether ultra-low-flow configurations exist that can meet stricter caps in jurisdictions.

Shutoff Performance and Run-On Protection

Reliability testing also investigates:

Maximum runtime in case of sensor faults-for instance, when an object is in the detection zone.

Shutoff response when hand removed, without any significant delay that would raise water use.

Behaviour during brownout or power loss—whether, for example, the solenoid fails closed, which would prevent continuous flow.

Well-performing touchless faucets in these tests can contribute measurably to the whole-building water budget and mitigate risks of flooding or custodial issues.

Controls, Accessibility, and Sensor Reliability

ADA and User Interface Considerations

Even though touchless faucets eliminate the need to grasp handles, their overall operable system is still assessed against ADA principles. Key aspects include:

Adequate clear floor space and approach at the lavatory.

Faucet placement and spout projection that enable operation within ADA reach ranges.

Any necessary manual override or mixing controls intended to be usable with one hand and with no more than 5 lbf of force, without tight grasping or twisting.

Tests for durability frequently include misuse scenarios: rapid, repeated triggering by users with mobility devices or accidental impacts that confirm the sensor window and spout and control housing remain aligned and functional.

Sensor Performance in Realistic Conditions

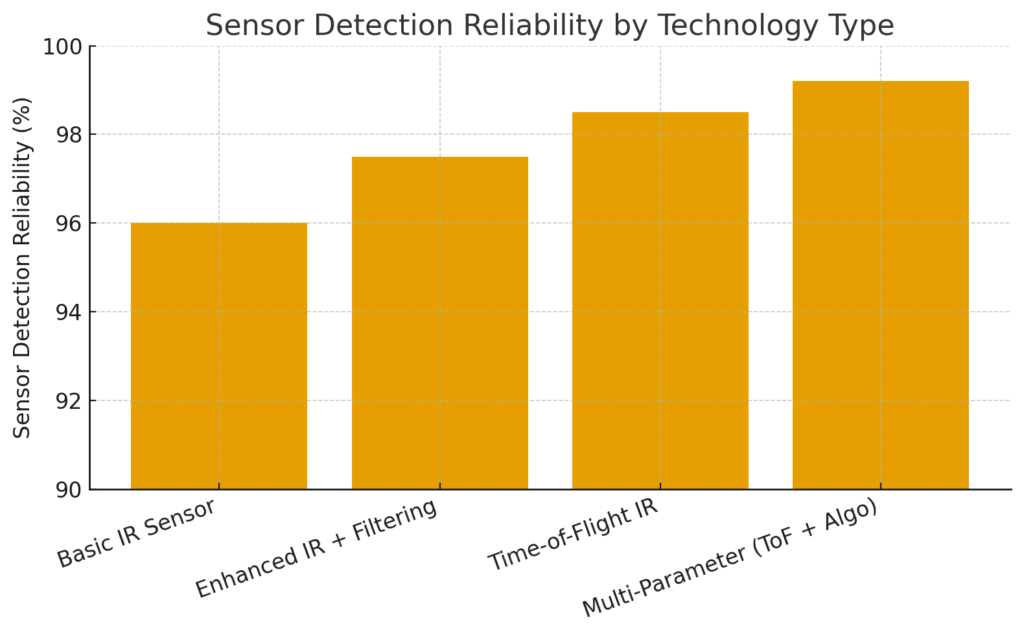

Sensor reliability testing goes beyond just cycle counts:

To confirm stable detection, ambient lighting variations, such as direct sunlight, fluorescent flicker, and LED lighting, can be simulated.

Different reflective and dark surfaces, like high-gloss countertops or matte black finishes, serve to challenge the detection algorithms.

Water quality variations in hardness and sediment are introduced to ensure that minor mineral buildup does not significantly degrade performance.

Generally, the systems that perform best use multi-parameter detection-for example, time-of-flight infrared combined with algorithmic filtering-and offer configureable detection ranges to adapt to basin geometry and backsplash conditions.

Power Systems, Maintenance, and System Integration

Power and Battery Life Testing

Long-term tests simulate the following for battery-powered configurations:

Daily use patterns that are realistic: peak usage periods, low-usage overnight profiles.

Auto-sleep and low-power modes between activations.

Periodic voltage sag and recovery.

A key outcome is an estimate of the battery replacement interval in a high-traffic setting, such as airports versus office buildings, having direct implications for O&M budgets and service planning.

Testing of hardwired faucets generally covers:

Surge protection against slight voltage fluctuations provides stability.

Separation of the low-voltage control wiring from line-voltage circuits according to electrical and plumbing codes.

Telemetry and BMS Integration

In more recent projects, particularly large campuses and smart buildings, touchless faucets are increasingly integrated into either the BMS or IoT platforms. Reliability evaluations now increasingly include:

Ensuring usage counters, error codes, and battery status are always reported through communication protocols such as BACnet/IP, Modbus, or proprietary gateways.

Where applicable, test firmware update processes to ensure that remote updates do not compromise key functions.

It translates into the following requirements for specifiers:

Faucets will provide data points of actuation count, valve fault, and low-battery status through the BMS interface.

“All networked components shall fail-safe to a closed-valve condition upon loss of communication or power.”

Implications for Specification and Design

Based on common durability and reliability test programs for commercial touchless faucets in public facilities, architects and engineers can refine their specifications to emphasize the following:

Standards compliance: explicit reference to ASME A112.18.1/CSA B125.1, ADA operable parts criteria, and WaterSense/CALGreen flow limits as applicable.

Life-cycle performance: requirements for successful completion of high-cycle tests-for example, several hundred thousand actuations or more-without leakage, loss of flow control, or sensor misoperation.

Environmental robustness: clear expectations for ingress protection rating, resistance to cleaning chemicals, and vandal-resistance measures such as anti-rotation mounting and tamper-resistant fasteners.

System integration such as telemetry, BMS integration, and diagnostics to minimize downtime and enable predictive maintenance.

Maintainability: service-accessible components-filters, solenoids, batteries; documented procedures; and recommended service intervals based on validated test data.

In this way, design teams can better validate their choices, reduce lifecycle risk, and ensure that public restrooms fulfill performance, sustainability, and accessibility goals over the service life of the building by basing product selection on documented test results supportive of recognized standards.

Summary Table: Testing Areas and Specification Notes

| Area | Main Focus | Typical Tests | What to Specify |

|---|---|---|---|

| Mechanical Durability | Long-term reliability of solenoid, seals, and mounting | Hundreds of thousands of actuations; checks for leaks and loosening | High-cycle durability, robust materials, anti-rotation mounting / reinforcement |

| Environmental & Ingress | Protection from moisture, chemicals, and abuse | Water spray/submersion, chemical exposure, vibration and pull tests | Required IP rating, resistance to cleaning agents, vandal-resistant housing and fasteners |

| Hydraulic Performance | Stable, efficient flow within code limits | Flow tests at 20/60/80 psi; before/after life-cycle checks | Design flow rate; compliance with ASME A112.18.1/CSA B125.1, WaterSense, CALGreen (0.5–1.5 gpm) |

| Controls & Sensors | Accessibility and reliable detection | ADA reach/force checks; varied lighting and surfaces; misuse scenarios | ADA-compliant operation (≤ 5 lbf, no tight grasping); multi-parameter or ToF sensors, adjustable range |

| Power & Integration | Battery life, electrical robustness, smart building functions | Simulated usage, voltage sag, surge tests; BMS/IoT communication trials | Expected battery interval; surge protection; BMS data points (usage, faults, low battery); fail-closed on power/comm loss |

| Maintainability | Ease of service over life cycle | Review of service procedures and intervals | Accessible filters, solenoids, batteries; documented maintenance schedules based on test data |

Source links and support documents

Location: Austin, TX

Profile: Sustainable design consultant specializing in low-flow, touchless water delivery systems. Focused on water conservation strategies and system integration for LEED and Green Globes projects.