Fluid Mechanics • Sensor Control • User Experience • Safety

Touchless toilets are the norm in public toilet now. They are hi-tech-looking, sanitary, plastic smile-hygienic, and water-efficient. Plastic smiles are surface detritus. One is seeing here a cosmology of delicate subtlety in spick-and-span-calibrated fluidics and engineering. All that one drop of water that flashes along clean from spout to valve is a result of spick-and-span-calibrated systems at work.

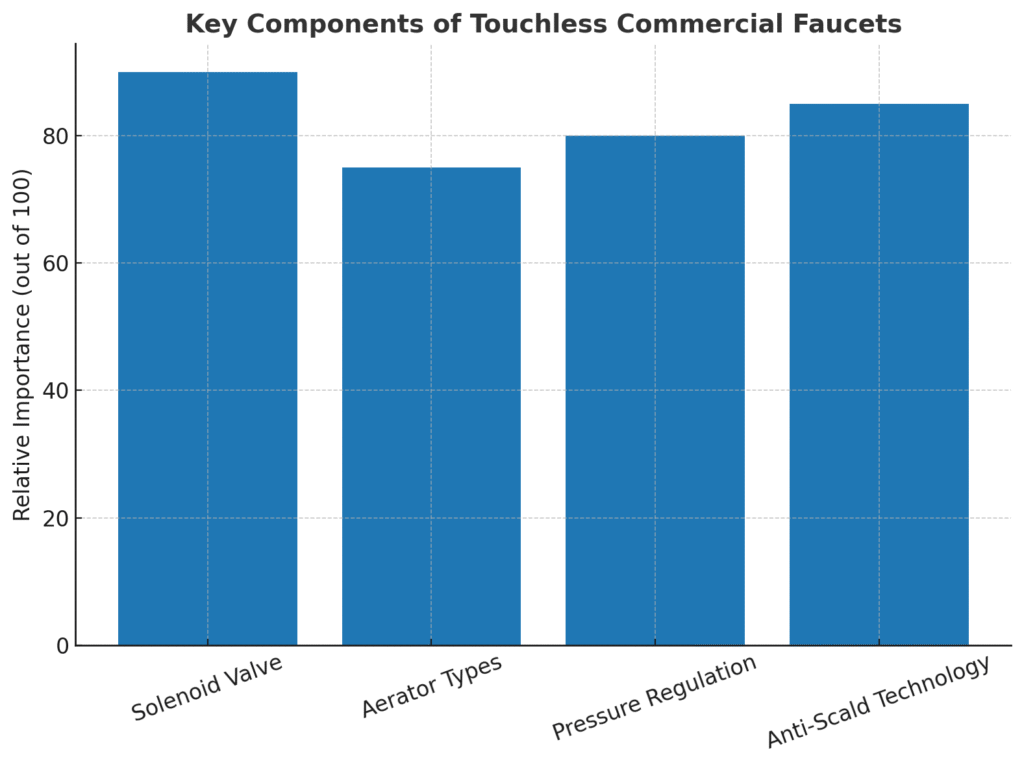

In this article, we’ll break down the fluid mechanics behind touchless commercial faucets, focusing on four essential components: solenoid valves, aerator types, pressure regulation, and anti-scald technology.

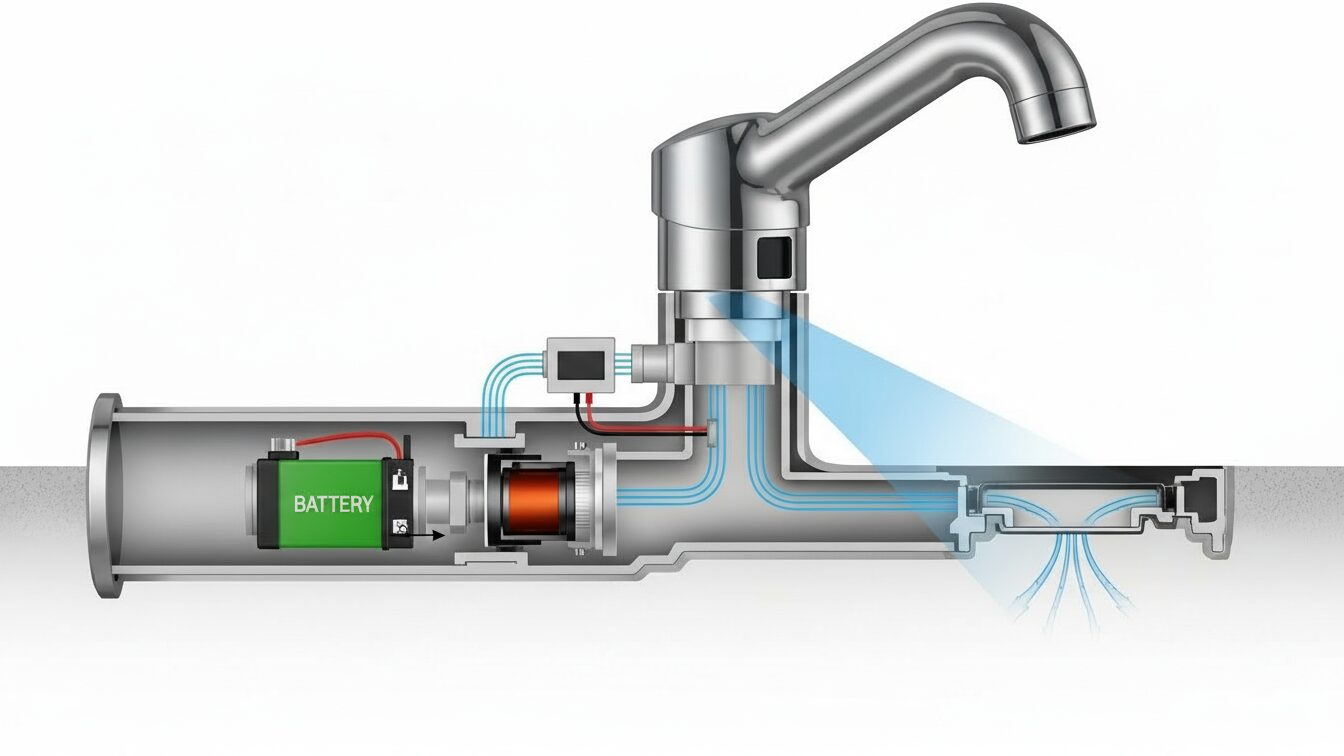

The Brain of the Faucet: Solenoid Valves

At the core of a touchless faucet’s functionality is the solenoid valve. This electromechanical device acts like a gatekeeper, controlling the flow of water with remarkable accuracy.

If fingers are inserted into the tap, the movement is sensed by the infrared sensor and triggers the impulse to the solenoid. The solenoid operates the valve to open and close by low-voltage electricity within a time frame of a fraction of a second, and water shoots out. If fingers are removed, the impulse is cut off and the valve is closed, and water is cut off.

It is this unobtrusive device which offers the touchless action, reducing contact and carryover of germs to a near zero. Solenoid valves offer economy too: to open and close in microseconds, and to control water flow where required. Commercial use, where dozens of hundreds of individuals will have used a restroom in a business day, that economy becomes dollars of water saved.

Aerator Types: Water Dispersion Physics

Faucet aerator can be a blazing but never an approved user experience. In addition to installing a screen on the tip of the spout, it also emulsifies air and water simultaneously to create a splashless smooth stream.

Facility managers have a choice of arrayed aerators in balancing water saving with user comfort:

- Standard Aerators: Mingles water and air into a full, unbroken stream that is natural-perceiving but splashing-reducing.

- Spray Aerators: Sprays water in very thin spray jets, for busy bathrooms where rinsing is most critical to effectively rinse drugs out.

- Laminar Flow Devices: Produces a clear, non-aeration jet for medical uses, where bacteria-conveyed air needs to be eliminated.

Aerators also limit flow rates. Flow is typically limited to 0.5 to 1.5 GPM on most commercial fixtures by water-saving codes. Through pressure control, it is possible for designers to provide even outflow of air in such a way that a feeling of heavy column of water is provided but less waters are consumed.

Pressure Regulation: Consistency Is Key

Industrial water facilities will supply a string of generic fittings to a big building. Hand pressure control is insufficient, and water supply will have more than sufficient to battle demand overall. Inside the faucet, it will switch between soft trickle and torrential gush.

Touchless pressure regulators of faucets ensure that there is a constant flow regardless of varying upstream pressure. They do so through the use of a diaphragm or piston capable of detecting the input pressure in a way in which the consumer receives constant flow at all times.

All such consistency also includes the convenience and usability factor. Flow-regulated as produced minimizes splashy water, conserves stress on interior components, and ensures aerators work efficiently. Most significantly, it makes faucets code compliant to at least the minimum regulated maximum flow rate for water efficiency.

Anti-Scald Technology: Safety Through Science

While touchless operation of the tap is prompted by efficiency and cleanliness, safety need not be excluded either. Public bathrooms need to recall that they are so designed as to be not even a factor for scald harm at least, especially in those otherwise such public bathrooms which otherwise are utilized otherwise by children, elderly, or physically disabled patrons.

That is where anti-scalding comes into the equation. Thermostatic mixing valves (TMVs) are certain touchless faucets that mix up the hot water and cold water before the spout. The valves continuously modulate output temperature and moment-by-moment correct supply fluctuation.

High priority given to instant cold water loss—to which is typically a contributor scalding—the TMV will operate to limit the supply of hot water to a lower pre-set, safe value. In other alternative case, safety levels being attained will shut off the valve.

Anti-scald systems not only protect lives but also remind facility managers of safety codes’ stipulations and therefore an ideal selection for health care, educational, and hospitality structures.

A Symphony of Parts

There is some purpose that all of those components must serve in it – solenoid valves, aerators, pressure regulators, and anti-scald technology. But the brilliance of a touchless business faucet is how each of those components is made to speak to each other.

- The primary principle of solenoid valve dispenses water only where and when it is required.

- Naerator provides flow for comfort and highest efficiency.

- Pressure regulator stabilizes even when there is system fluctuation.

- Anti-scald valve ensures users’ safety.

They offer a faucet that not only shouldn’t be touched but is safe, inexpensive, and reliable too, which every workplace wishes to possess.

The Future of Fluid Mechanics in Faucets

The more recent the technology, the more intelligent the faucets. Either IoT or Bluetooth enabled so that facility managers can view water consumption, leak notification, and remote operation of controls. Others are exploring retro-fitting high-end usage-saving aerators without sacri- ficing comfort.

What never changes is middle-of-the-road reliance on fluid dynamics made affordable. Valve to spout, technologies come together in the middle to give us the touchless, headache-free faucet convenience we’ve grown to expect in public restrooms.

Conclusion

Mass-market touchless business-style faucets aren’t luxury fixtures just-they’re an automated fluid dynamics system. Solenoid valves offer quick response, aerators refine the water jet, pressure regulators ensure smooth flow, and anti-scald technology ensures user protection.

Since technology has reached such a level of standing, facility planners and managers can now make well-informed decisions during the installment of faucets, not just offering efficiency and cleanliness but comfort and safety as well.

Next time you wave your hands in front of an auto faucet, pause for a moment and thank the high-tech magic. Each drop is the result of a high-tech ballet of valve, regulator, aerator, and mixer—a soundless water control orchestra which makes toilets today flush so easily.

Component overview table

| Component | Function | How It Works | Benefits |

|---|---|---|---|

| Solenoid Valve | Controls water flow in response to sensor signals | Ultra-fast opening/closing when sensor detects or loses hands | Reduces touchpoints (sanitation), conserves water, rapid and precise control |

| Aerator Types | Shapes and conditions the water stream | Mixes air with water or alters flow pattern | Smoother splashing, comfortable, conserves water |

| Pressure Regulation | Charges constant flow despite supply fluctuation | Levers diaphragm/piston to try to control water pressure | Constant flow, prevents equipment damage, allows aerators to flow as required, complies with code regulation |

| Anti-Scald Technology | Protect consumer from hazardous water temperature | TMVs mix hot/cold water and control in real-time | Scald protection guaranteed, guaranteed safe delivery, safety standards achieved (hospitals, schools, etc.) |

Source links and references

Location: Austin, TX

Profile: Sustainable design consultant specializing in low-flow, touchless water delivery systems. Focused on water conservation strategies and system integration for LEED and Green Globes projects.