Luxury • Sanitation • Convenience • Efficiency

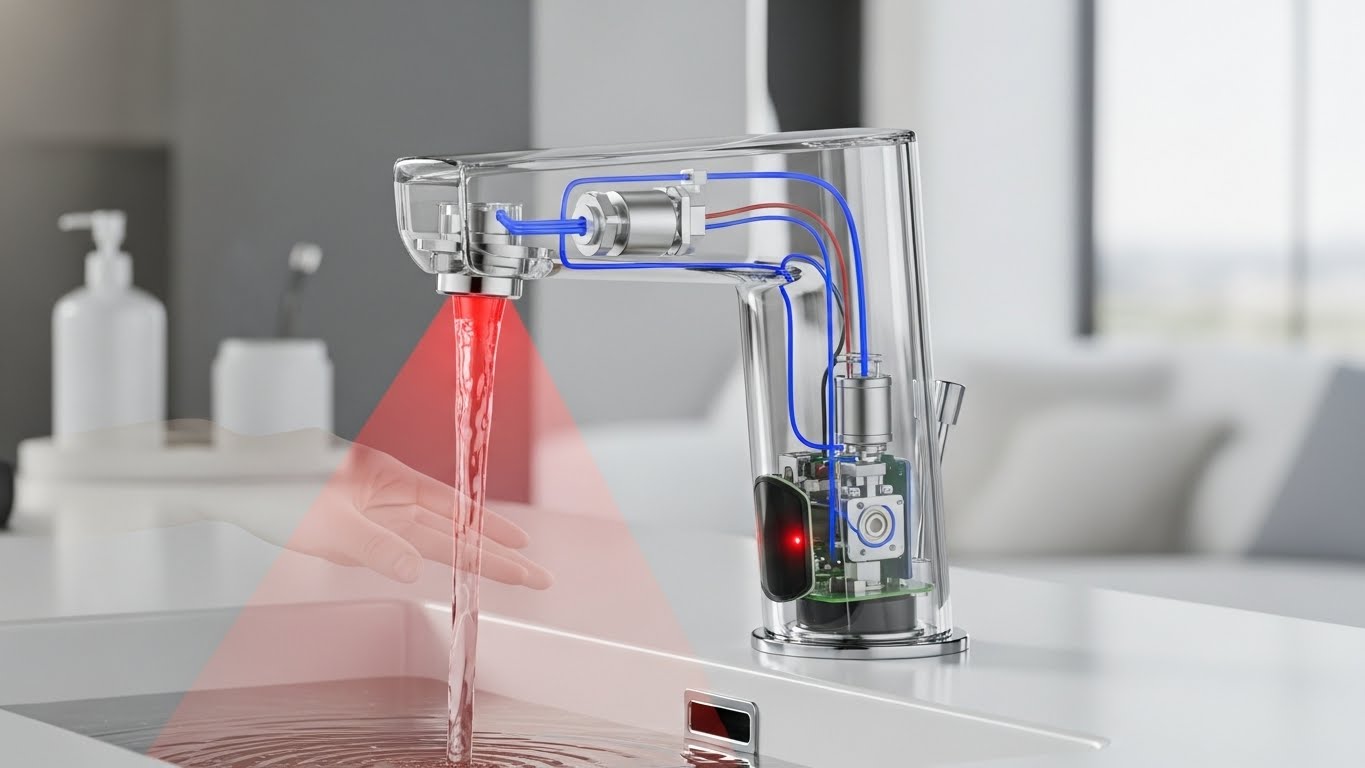

Touchless faucets are going mainstream for hospital, commercial restroom, even upscale home kitchen design. They’re the height of luxury sanitation, convenience, and efficiency—but behind the eye of the design storm is a gorgeous marriage of sensor technology and water flow engineering. To take a peak inside out of what’s going on when they’re turning off and on, we must bare the styling that makes them intelligent but not zany.

In this article, we’ll explore how infrared sensors and radar-based sensors differ, how engineers optimize response times, the systems that prevent false triggers, and the logic behind precise water flow control.

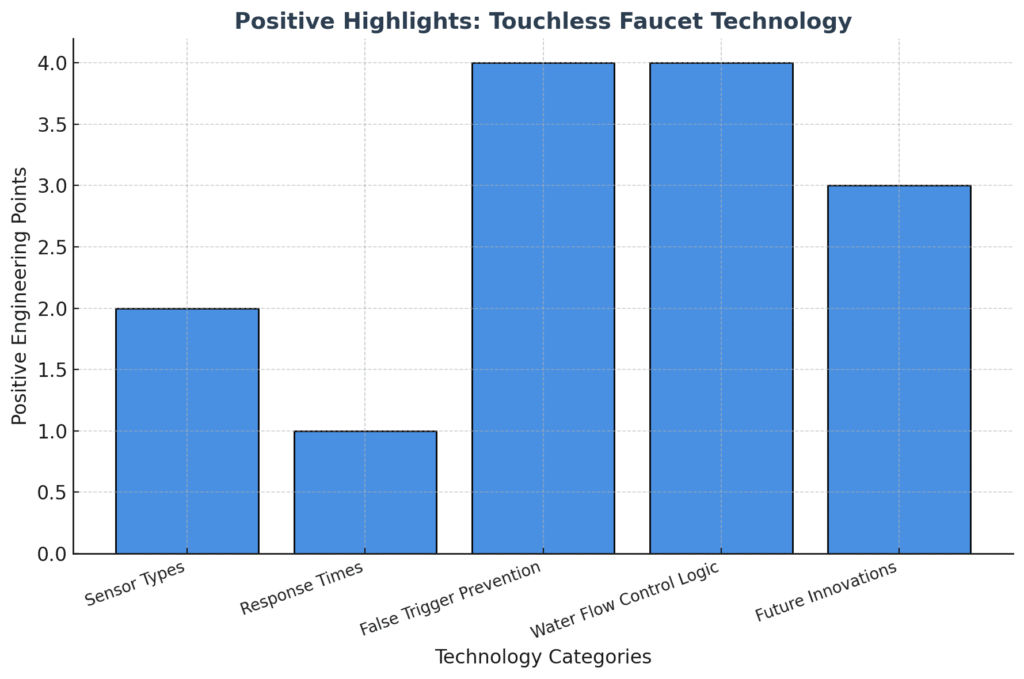

Infrared vs. Radar Sensors

The heart of a touchless faucet is the sensor. The sensor detects the hand presence and tells the solenoid valve to release water. Two main sensing technologies exist: infrared (IR) and radar (microwave) sensors.

Infrared Sensors

It is also employed in touchless faucets. Infrared sensor emits an imperceptible infrared light beam. Light will get reflected back from the top surface of hand or arm held length of object when it returns. It will be sent back to the sensor and will activate the faucet to open.

- Disadvantages: Not very precise, lots of interference, and inappropriate for more than one object.

- Weak areas: Dirty radar through intensity of ambient illumination, reflectivity of reflector material, or dirt on sensor window.

Radar (Microwave) Sensors

Microwave sensors utilize radio waves of high frequency rather than light. Microwave sensors transmit constant or pulsed microwave power, bounce off moving targets toward the sensor and back detected by the sensor. Sensor on/off travel in distance operates faucet on/off.

- Less impairment of poor performance in decreasing light, high humidity, or IR-absorbing environments.

- Less costly, more prone to false alarm when properly installed, and power-hungry compared to infrared.

Commercial engineers will place IR in bathrooms but place radar sensors in corporate cafeteria or hospitals where fingers are never inserted into the faucet.

Engineering Response Times Science and Mathematics

Least likely optimum compromise of sensor reaction—is reaction time on finding hand.

- Common Reaction: Home faucets turn on in 0.25–0.5 seconds. This compromise bamuses people with no “false starts.”

- Engineering Compromises: Turn on so rapidly as to damp transients. Not popular if too slow. Engineers use digital filtering software in the system so detection is achieved but not purchased with delay.

Premier faucets offer response time adjust where facility professionals set speed or save by use.

False Trigger Prevention

Random triggering is touchless faucets greatest design flaw. Leaks from faucet are horror show, worse, customer loss of confidence. Designers have available all types of preventive design:

- Designed Detection Zones – Hand is detected by sensor at distance, i.e., 2–6 inches from spout. Person walking by won’t trigger it.

- Signal Processing – IR and radar sensors both have noise-killer software packages integrated. Activity or lightning nearby, i.e., isn’t detected.

- Time Delay Buffers – Most of the faucets are rubbed to give an arrangement where a one-minute (i.e., 0.2 seconds) time delay is provided before sensor activation. It is tried as an anti-spurious activation protection function due to short-time noise light or due to transient drift over objects.

- Material Shielding – Chrome countertop or stainless-steel sinks shield the sensor housings from interference.

Due to multi-levels design, the newly developed touchless faucets run at 95–98% under application operating conditions when installed.

Water Flow Control Logic

The water flow control is handled by the control module through hand detection through the sensor. It’s an electronic and hydraulic problem.

Solenoid Valve Operation

Since detection itself is sensed by the filter, it will release a solenoid valve—fast-opening, fast-closing electromagnetically operated valve. The solenoid provides good control of water flow with shut-down facility for ready withdrawal of hands in order to open.

Timing of Flow and Safety

30–60 seconds run times are standard in touchless faucets. This will avoid flooding on sensor damage or where loss of detecting space is involved.

Control of Flow Rate

As far as control saving and cleaning are concerned, the faucets are metered to release water in flow rates 0.35–0.5 GPM for commercial application. Stream is metered with pressure regulators and aerators to obtain maximum user comfort and splash protection.

Adaptive Control

Learning luxury faucets: sensor system modulates habits and sensitivity reduction or shut-off time to the requirement of an environment—a public airport toilet versus office toilet.

Future of Faucet Sensor Technology

Touch faucets are also in the making in the near future because of smart sensors and artificial intelligence. They apply multi-sensor fusion (IR, and radar) to be almost perfect in the first generation. Others apply Bluetooth and IoT to provide real-time visualisation of water used by facility managers.

Technology in the future will even be able to make one receive gestures where one waves one’s hand whatever way one wants to control temperature or movement—never even having to hold a handle at all.

Conclusion

Mass consumers purchase touchless faucets by themselves but, as in the case at hand, they get the high-order design product. With infrared or radar sensor technology high-order design to response time optimized to accuracy level, high-order anti-frill trigger security, and designer-specified control logic for water flow control, all for best hygiene, reliability, and efficiency.

Homeowners, renters, and building owners will soon discover why touchless faucets are plumbers’ worst-kept secret—and worst to copy.

Summary Table

| Category | Details |

|---|---|

| Sensor Types | Infrared (IR): Infrared light reflection off; cheap, very short range. Radar (Microwave): Detection of radio waves; great low light/moisture detection, will pick up general motion but more expensive and power-hungry. |

| Response Times | Typically 0.25–0.5 sec to respond. Startle equilibration speeding reaction. |

| False Trigger Prevention |

1. Detection Regions: Calibration 2–6 inches. 2. Signal Processing: Ambient noise/light filtering. 3. Time Delay Buffers: Functions persistence (e.g., 0.2s). 4. Material Shielding: Reflected surface interference minimized. |

| Water Flow Control Logic |

– Solenoid Valve: On/off simple water. – Max Run Timer: 30–60 seconds leakage protection. – Flow Rate: Commercial-grade at 0.35–0.5 GPM standard. – Adaptive Control: Sensors are learned and adapted sensitivity/timing. |

| Future Innovations |

– Multi-Sensor Fusion (IR + radar). – IoT Connectivity for remote water control. |

Source links and support documents

Location: New York, NY

Profile: Commercial restroom design expert. Works with architects and facility managers to integrate touchless aviation faucets into airports, office towers, and mixed-use developments with ADA and code compliance.