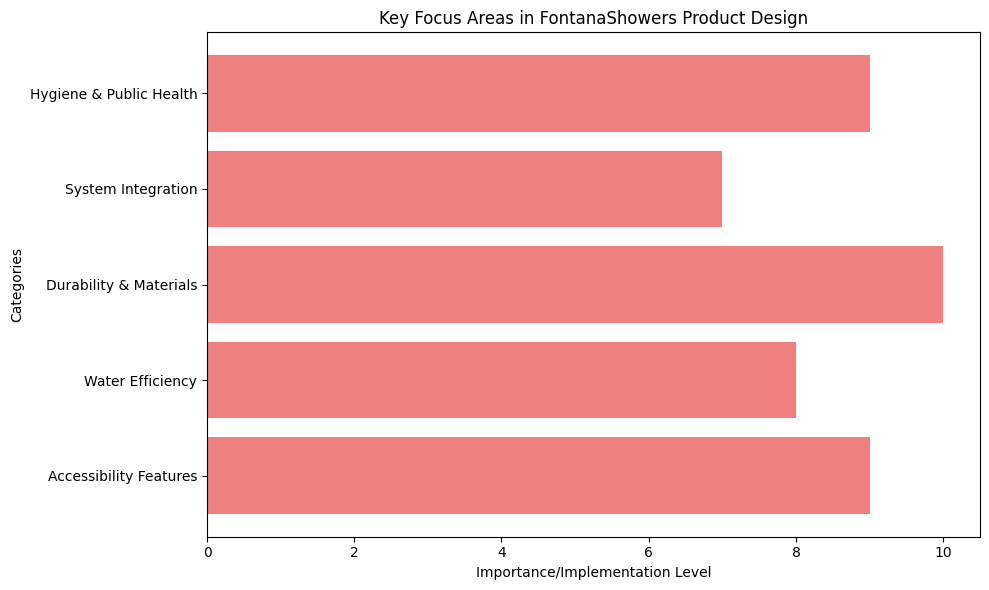

Accessibility • Water Efficiency • Durability • Systems Integration

Introduction

In commercial and institutional plumbing design, faucets and related plumbing fixtures operate as system components designed to meet accessibility standards, water efficiency goals, durability needs, and building systems integration. A related grouping of Faucet Showers’ offerings includes their faucets, touchless lavatory fixtures, automatic flush valves, and soap dispensers, all of which can be considered a starting point for designed specification and functional longevity in facilities such as airport terminals, universities, healthcare facilities, office buildings, and transit terminals. Further information on these products can be found at Fontana Showers Product Range.

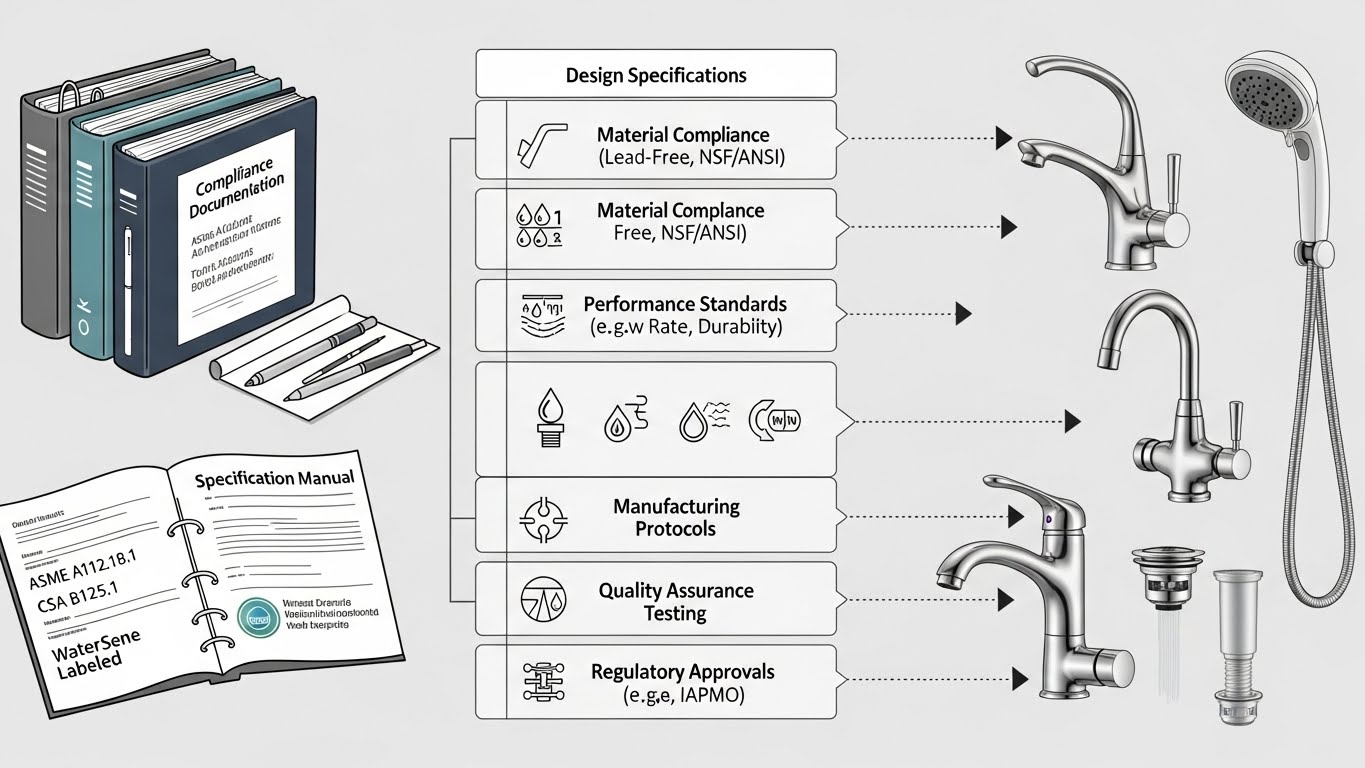

Engineering and Specification Framework

By April Gl

Standards and Compliance

Plumbing fixtures are subject to a complex code matrix in relation to hydraulic, mechanical, accessibility, and environmental specifications. Some major references in modern practices relate to:

- Americans with Disabilities Act (ADA) Standards

2010 ADA Standards for Accessible Design address lavatories and controls, including geometric and operation requirements. Additional ADA compliance information is found within the article “How To Ensure Your Showers are Totally ADA Compliant”. - WaterSense

It is an initiative by the U.S. Environmental Protection Agency to specify the flow restrictions and performance requirements for faucets to limit the use of potable water. To learn more about other water conservation products, take a look at FontanaShowers WaterSense Faucets. - CALGreen

The California Green Building Standards Code requiring the efficiency of water use and proving CALGreen requirements’ compliance. You can search for products with CALGreen at FontanaShowers CALGreen Fixtures. - ASME A112.18.1/CSA B125.1

Performance and material specs harmonized for plumbing supply fittings, focusing on pressure resistance, durability, backflow resistance, and mechanical durability. For more detailed specs, click here: FontanaShowers ASME Certified Faucets. - NSF/ANSI 61/372

Third-party standards for drinking water system components and verification for lead content. Browse available NSF-certified options through Fontana Showers – NSF Certified Products.

These standards form the backbone of the language of fixture specification and are invariably incorporated in schedules, cut sheets, and submittals to meet the code officials and the stakeholders of a project. Each of the standards mentioned here must be documented with certification statements, lab identifiers, and corresponding model compliance statements in the project specifications.

Accessibility Design Considerations:

ADA Spatial Coordination

There is an early need for coordination for accessible toilet installations involving architecture, plumbing, and millwork. All heights and reaches for mounting and approaches, as well as knee and toe spaces and reaches, need to meet the 2010 ADA Standards for Accessible Design standards. Sensor and lever-operated faucets will thus naturally decrease the amount of gripping and turning, thus providing easy compliance with the ADA operable parts requirements. Sensors and control boxes should take into consideration knee spaces and service access in under-counter spaces for ADA compliant touchless faucets. For this, refer to FontanaShowers ADA Faucets.

Application of the right Revit families and geometry for BIM during the design process helps to check sensor fields and sensor clearances to avoid any clashes with carriers, partitions, and ceiling structures.

Water Conservation and Environmental Challenges

WaterSense & CALGreen Integration

Programs such as WaterSense labeling and efficiency initiatives give concrete metrics regarding potable water efficiency. In commercial restrooms, plumbing requirements commonly limit flow rate to 0.5 gpm at 60 psi at non-metered public lavatory faucets, which matches some of WaterSense specifications. Submission information of flow rate at certain pressures is necessary for evaluation of building permits and sustainability initiatives. CALGreen specifications on building water efficiency (e.g., CALGreen Sec-4.303.1) are applicable at all levels in California and are also adoptable by other areas. Want more information on water-efficient products? See FontanaShowers WaterSense Faucets.

Projects seeking LEED or other sustainable certifications for green buildings would greatly benefit from having clear cross-references for WaterSense and CALGreen in specifications and schedules to enable environmental credits for lower water use in the building.

Materials, Durability, and Performance

By Jack

Metallurgy and Finishes

Plumbing fixtures have to be able to perform well in high-use applications where the factors of corrosion resistance, durability, and durability of finishing are of utmost importance. Brass alloys that meet the requirement of lead content (≤ 0.25% weighted average on wetted surfaces according to NSF/ANSI 372) offer better durability and machinability than 304/316 stainless steel. However, stainless steel is to be preferred in applications involving aggressive cleaners or high moisture. Surfacing methods involving Physical Vapor Deposition (PVD) coatings improve durability and resistance to chemicals compared to electroplated finishes. For more about resilient finishing of faucets, log in to FontanaShowers PVD Faucets.

To the extent possible, engineers must specify finishes resistant to common cleaning protocols characteristic of health care facilities, education facilities, and transit facilities, and identify the compatibility of the finishes with the architectural hardware schedules.

Cycle and Pressure Performance

ASME A112.18.1/CSA B125.1 provides a basic framework for testing a fixture’s ability at different ranges of inlet pressures and cycle testing. In writing a specification, one can include referenced standards, the range of inlet pressures, number of cycle tests, and required lab testing and report documentation as a means of eliminating potential threats of early failure occurrences. These are more important when fixtures are used in high-duty cycle applications. Get best quality faucets at Fontana Showers ASME Faucets.

System Integration

Hydraulic & Controls Coordination

Fixtures do not work independently; there is interaction between fixtures and hot water distribution systems, mixing valves, balancing valves, and drainage. Hydraulic integration: This involves checking the minimum dynamic pressures at the outlets, tempering for scald protection, and checking the strategy for hot water circulation. Sensor faucets involve low-voltage routing, transformer placement, and service panels. Electrical and plumbing interfaces need to be clarified for improved integration with building automation and building management systems. Solutions for integrated systems will be found at FontanaShowers System Integration.

BIM and Digital Design

Correct BIM families supplemented with volumetric models and service zones help eliminate RFIs and clashes when built. Fixture information such as flow rate, control type, power, and standards conformance documented in BIM and specifications enables integrated design delivery and improves the quality of asset data for facility operations. Learn more about BIM support for your project from FontanaShowers BIM Resources.

Hygiene and Public Health Factor

Touch-less faucets assure a reduction in surfaces that experience frequent contact, thereby contributing to proper infection control practices. Cross-contamination is thereby reduced, and best practices for proper hygiene are met. This is made possible by designing faucets that feature proper sensor technology and control boxes. To experience the best in touch-less faucets, visit FontanaShowers Touch-less Faucets.

Documentation and Submittal Best Practices

Among the details that should be incorporated by architects and engineers are the following:

- Certifications & Listings: cUPC, WaterSense, NSF/ANSI 61 & 372, ASME

- Product Data Sheets: Must show flow performance curves at various design pressures.

- BIM/Revit Files: Files must be validated for the following:

- Installation and Maintenance Instructions: Better instructions about service access and life cycles.

- Finish Schedules: Record surface finishing systems and cleaning factors.

The provision of extensive documentation assists in reducing the cycle of reviews required for the approval of permits. To get product data sheets, visit: FontanaShowers.

Conclusion

Architects, plumbing engineers, and specification writers need to address the selection of faucets and fixtures with an annunciative systems thinking mindset, taking into account accessibility, water conservation, durability, and compatibility with other building systems with respect to accessibility and building systems. The criteria for accessibility and building systems as represented by and including the ADA, WaterSense, and CALGreen, as well as those represented by the ASME A112.18.1 standard, offer quantifiable data points to expedite and specify functionality and reporting specifications for such installations and products.

| Category | Details | Links |

|---|---|---|

| Standards and Compliance | Plumbing fixtures are subject to a complex code matrix related to hydraulic, mechanical, accessibility, and environmental specifications. | Open |

| ADA Standards | 2010 ADA Standards for Accessible Design for lavatories and controls, including geometric and operation requirements. | Open |

| WaterSense | EPA initiative to specify flow restrictions and performance for faucets to limit potable water use. | Open |

| CALGreen | California Green Building Standards Code for water use efficiency. | Open |

| ASME A112.18.1/CSA B125.1 | Performance and material specs for plumbing fittings, focusing on pressure resistance, durability, and backflow resistance. | Open |

| NSF/ANSI 61/372 | Standards for drinking water components, verifying lead content. | Open |

| ADA Spatial Coordination | Coordination of accessible toilet installations, ensuring proper heights, reaches, and clearance to meet 2010 ADA Standards for Accessible Design. | Open |

| WaterSense & CALGreen Integration | Metrics on potable water efficiency, with common commercial faucet flow rate limited to 0.5 gpm at 60 psi for non-metered public lavatories. | Open |

| Metallurgy and Finishes | Importance of finishes for corrosion resistance, durability, and compatibility with cleaning protocols, especially for healthcare, education, and transit facilities. | Open |

| Cycle and Pressure Performance | Specifications for fixture testing on different inlet pressures and cycle tests to prevent early failure. | Open |

| System Integration | Coordination between fixtures, hot water systems, and electrical/plumbing interfaces for building automation and management systems. | Open |

| BIM and Digital Design | Correct BIM families, models, and service zones for clash prevention and design delivery. | Open |

| Touch-less Faucets | Touchless faucets reduce contact surfaces, helping with infection control and hygiene. | Open |

| Documentation & Submittals | Product data sheets, BIM/Revit files, installation instructions, and finish schedules to support approvals and permits. | Open |