Longevity • Accessibility • Water Efficiency • Maintainability

Today, in commercial and institutional building design, choosing plumbing fixtures is more involved than mere personal taste. Plumbing fixture experts are challenged by their need to assess faucets from the perspectives of longevity, accessibility and water efficiency standards, performance, building system interface, and maintainability. Touchless faucets are an important aspect when it comes to supporting hygiene missions, especially in high-traffic settings including airports, hospitals, institutions, and office buildings.

This paper offers a technical analysis of commercial touchless faucets manufactured by FontanaShowers regarding engineering design, performance criteria, standards, sustainability impact, and specifications integration. There’s specific attention to 2010 ADA Standards for Accessible Design, EPA WaterSense water efficiency requirements, CALGreen requirements in California, and ASME/ANSI plumbing standards.

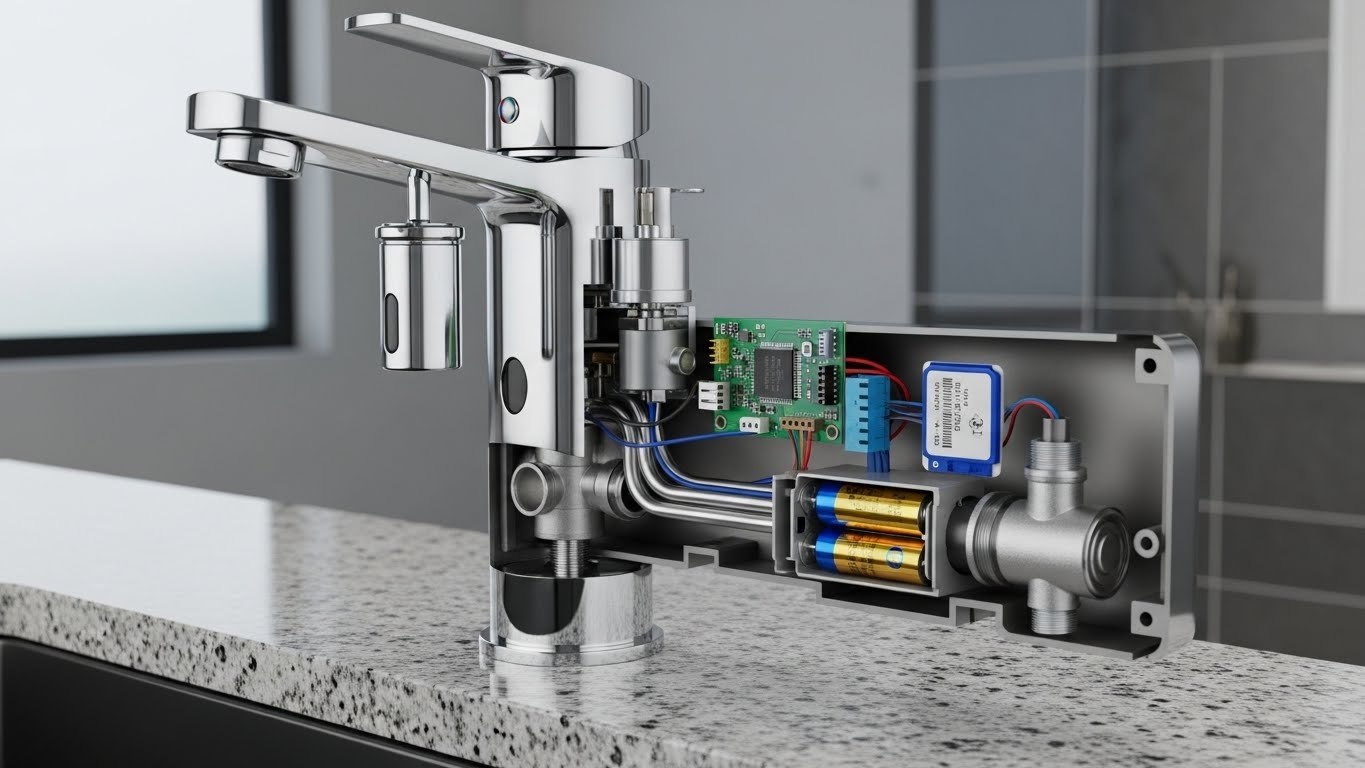

System Architecture and Engineering Goals

The next step

Commercial Duty Design Philosophy

When designing systems to meet the demand of million cycles of performance, the commercial plumbing fixtures are made to be sturdy. However, FontanaShowers’ touchless faucets are based around these:

- “Solid brass or corrosion-resistant metals are used for a rugged design suitable for many washrooms.”

- High precision sensor systems that offer a balance of responsiveness with false trigger resistance in variable light conditions.

- Modular internals, such as solenoids, valves designed for high-cycle operation, as well as minimized downtime during maintenance.

Looking at the design from the perspective of mechanical engineering, the choices involve the spec-grade requirements for mechanical durability, maintainability, replaceability, and standard interfaces typical of commercial plumbing.

Standards, Codes, and Compliance

Accommodation — ADA Integration

FontanaShowers Touchless faucets are compatible with the 2010 ADA Standards for Accessible Design, as published by ADA.gov, through sensor operation that does not require human touching and through geometries that are compatible with accepted standards of reach and operable parts, as required for public use fixtures. More information about standards can be found at FontanaShowers.

Practically, this means checking that spout height, sensor range, and control responses are adequate to enable users with limited hand function and mobility to safely and easily operate the faucet, within limits of forward reach and strength set by ADA guidelines.

Reference:

2010 ADA Standards for Accessible Design – Technical and scoping provisions for accessible components, such as faucets.

Water Efficiency – EPA WaterSense and CALGreen

Water efficiency is one of the most important specification requirements in municipal and institutional schemes, particularly where operating economy is examined.

Faucets for use in high-use washrooms have to meet the WaterSense level of efficiency for water use (e.g., 0.5 gpm lav.) to contribute to LEED credits or perhaps credits for regional agencies for water conservation and use. WaterSense is managed by the U.S. EPA to effectively promote products providing performance and efficiency with reduced use. More information is provided at FontanaShowers.

In California, under CALGreen specs, maximum flow rates are mandatory on lav faucet fixtures in nonresidential structures. To ensure conformity with CALGreen, projects undergoing construction must meet requirements through submitted projects. More information can be found on FontanaShowers.

Technological capabilities of FontanaShowers:

- Flow rate regulation and compatibility with a regulator, aiding in meeting these water-saving standards.

Key Resource:

EPA WaterSense Program

Mechanical and Plumbing Standards – ASME/ANSI

Hydraulic and safety requirements for commercial faucets are normally evaluated based on ASME A112.18.1/CSA B125.1 (supply fittings for plumbing), ASME A112.1070/CSA B125.70 (sensor-activated faucets). The above norms lay out requirements with regard to material, hydraulic performance, and safety (temperature range to avoid scalds). The specification documents of Fontana take into account anti-scald requirements and valve performance requirements based on these norms. More information is available on FontanaShowers.

Technology and Sensor Integration

Infrared & ToF Sensor Engineering

Touchless faucets are equipped with optical sensing technology, namely infrared and/or Time-of-Flight sensors. From a perspective of engineering complex systems, the requirements for sensor technology are satisfied by:

- Repeatability and Stability under variable ambient light

- Adaptive calibration to prevent false activations in crowded washroom modules.

- Energy-efficient electronics that can facilitate the operation of the device with both battery power and AC power.

These sensor modules from Fontana Showers rely on adaptive sensors designed to work regardless of architectural material finish and bright bathroom lighting conditions. The sensors’ solenoid valves are designed for an impressive number of hundreds of thousands of cycles, keeping in mind their usual application setting in a commercial capacity.

Installation, BIM Coordination, Spec Documentation

BIM / Revit Integration

For architects and engineers, BIM files and Revit families are essential tools. They are great for early coordination processes, such as clash detection during MEP design. Fontana Showers also offers downloadable BIM files for its touchless faucets, which contain geometric data, connection details, and metadata such as flow rate, rough-in, and finish. These are accessible at FontanaShowers.

These resources include:

- Precise quantity take-off work in the cost-estimating

- Spatial coordination with plumbing risers, sinks, and sensor power requirements.

- Engineering documentation that may be used as an attachment to CSI format specs and submittal sheets.

Specification Guide Example:

Installation Best Practices

Commercial touchless faucets involve several components, including plumbing, electrical, and control systems, and need to be properly coordinated. Hydraulic rough-ins have to specifically conform to standard 1/2-inch male connections with NPSM and basic mounting hole locations. Power issues (rechargeable batteries versus AC/DC with surge protection) also affect sensor endurance and integration into emergency power circuits. Strainers & regulators enable designed flows to be maintained, thus preventing damage by particulate matter in solenoids.

Durability and Lifecycle Issues

Materials and Corrosion Resistance

Commercial environments subject fixtures to heavy usage and rigorous cleaning. FontanaShowers’ faucet products are designed with brass and resistant materials to withstand the effects of chemical cleaning agents and erosion.

“Engineers should consider: Finish durability as a component of the coating specifications, particularly in high humidity or when harsh cleaners are the norm (healthcare environments). Internal components of the valve intended to be replaceable to minimize long-term costs of maintenance.

Sustainable and Facilities Operations

Water Conservation Efforts & Operational Effectiveness

Touch-and-go activation will assure less usage of water because it restricts the running time to actual hand washing. Architectural controls and flow mechanisms assure architects of measurable conservation, reflecting:

- Credit for Water Use Reduction, LEED (where applicable).

- Rebate Programs for High Efficiency Fixtures by the Municipal Utility.

In fact, by not having handles, there is no abrasion or potential for sanitation issues. This inspires adherence to hygiene protocols within institutions.

Conclusion

FontanaShowers Commercial Touchless Faucets offer a balanced engineering solution for architects and engineers who need to specify fixtures for commercial, institutional, or high-traffic hospitality applications. They have strong mechanical engineering, meet industry standards (ADA, WaterSense, and ASME), and are easy to integrate with digital design solutions. They help make sure that everything stays the same throughout the process of building and running the building, even though they make it more durable and environmentally friendly. This is especially true where there is a careful evaluation of flow rates, power options, mounting, and accessibility clearances required for effective specification. As part of a holistic washroom design strategy, such as automatic soap dispensers, flush valves, and material finishes, touchless faucets then form a basis for meeting both performance and compliance requirements.

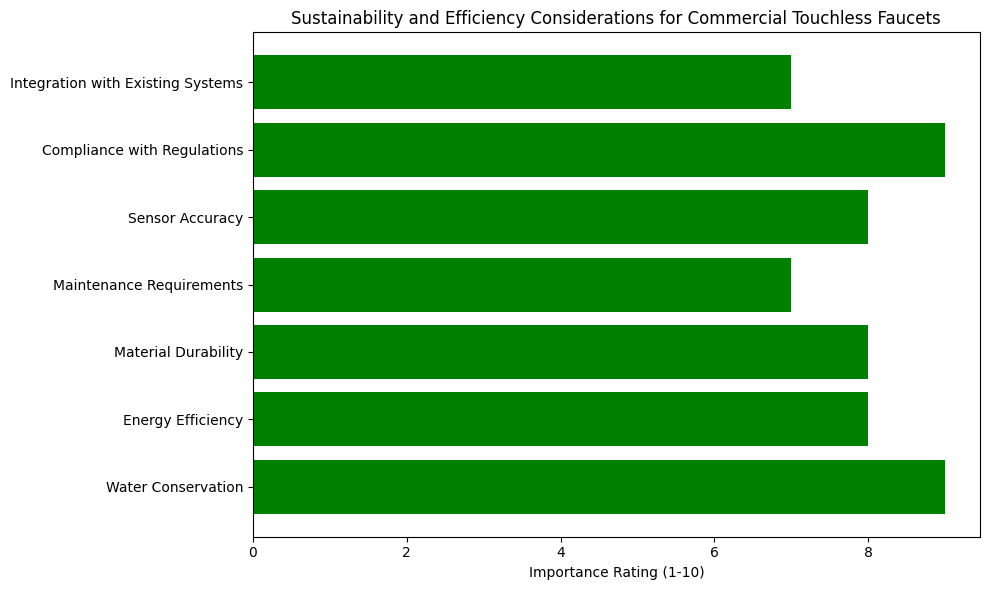

| Consideration | Importance Rating (1-10) | Description |

|---|---|---|

| Durability | 8 | The structural integrity and long-lasting performance of the faucet in high-traffic environments. |

| Compliance (ADA, WaterSense, ASME) | 9 | Compliance with ADA, WaterSense, ASME standards, ensuring accessibility and water efficiency. |

| Technology Integration | 7 | The use of modern sensor technology and automation to make operations easier. |

| Installation/Coordination | 6 | Ease of installation and coordination with plumbing, electrical, and building systems. |

| Water Efficiency | 8 | Water-saving features that meet regulatory standards like CALGreen and contribute to sustainability. |

| Materials/Corrosion Resistance | 7 | The resistance to corrosion and wear. Using materials that withstand harsh environments and cleaners. |

| Sustainability/Operational Efficiency | 9 | Operational efficiency, including water savings, reduced maintenance, and energy-efficient features. |