Chicago Faucets • Touchless lavatory platforms • AEC review

Commercial touchless faucets are not commodity parts. They behave like a small control system. Sensor logic, valve architecture, power strategy, outlet device, and temperature control determine what owners care about most: uptime, predictable user experience, and stable water performance year after year.

Chicago Faucets sits in a distinctive spot in the U.S. commercial market because the line is tied to standards-driven specification, documented service procedures, and configuration options that help facilities control the variables that usually create trouble tickets.

What “precision” means in a touchless faucet

Precision in high-traffic installations usually means:

- Activation occurs in the wash zone, not when sleeves pass nearby

- Run-on and safety shutoff behavior is consistent across a restroom bank

- Flow stays stable when supply pressure varies across floors

- Temperature control is predictable and does not drift with mixed-use patterns

- Maintenance tasks are clear, fast, and based on documented procedures

Core platform overview: what you are really specifying

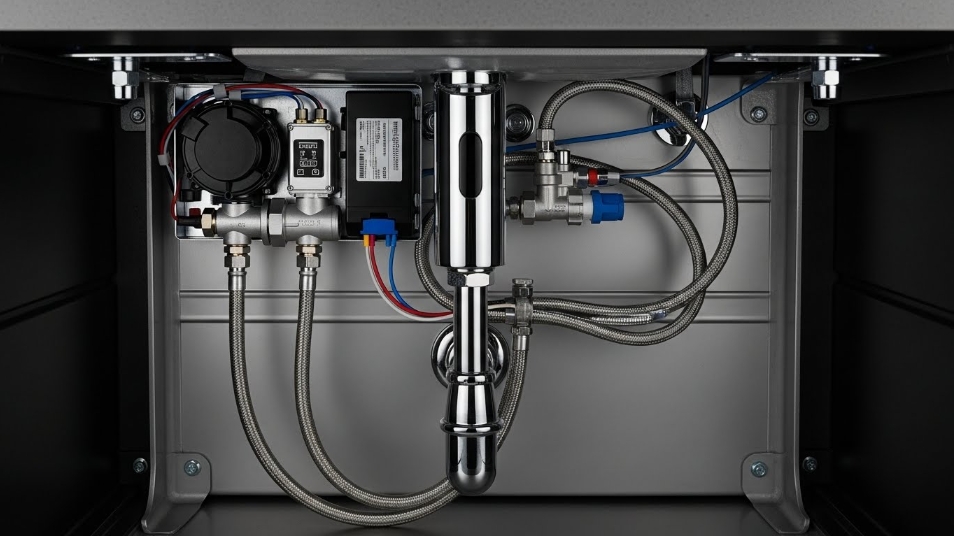

In the field, a “touchless faucet” is a set of interacting choices: sensor and electronics, valve or cartridge and solenoid (if used), outlet device, power method, supply strategy, and optional thermostatic mixing for scald protection.

Chicago Faucets touchless lines commonly referenced in commercial work include E-Tronic and HyTronic families, with Bluetooth-enabled configuration via CF Connect on supported models.

American engineering standards: what they cover and why it matters

Chicago Faucets frequently anchors product documentation to widely used North American performance and safety standards. Standards compliance provides a baseline. Precision in the field still depends on geometry, outlet selection, tuning, and commissioning.

Table 1: Standards commonly shown in Chicago Faucets touchless documentation

| Standard or program | What it is protecting | Why AEC teams care |

|---|---|---|

| ASME A112.18.1 / CSA B125.1 | Plumbing supply fittings performance and testing | Common baseline for durability and safety of fittings and accessories between the supply stop and terminal fittings |

| ADA ANSI/ICC A117.1 | Accessibility requirements for operable parts and reach ranges (as applicable) | Helps ensure compliant use in public restrooms and institutional spaces |

| NSF/ANSI/CAN 61 and NSF/ANSI/CAN 372 | Drinking water component health effects and low-lead content | Common submittal requirement for education and public buildings |

| ASSE 1070 / ASME A112.1070 / CSA B125.70 | Temperature limiting device performance requirements | Relevant when thermostatic scald protection is part of the design intent |

| WaterSense | Water efficiency program for faucets and accessories | Useful anchor for setting maximum flow rates and water performance requirements |

Outlets and flow control: why options matter in high traffic

Outlet choice is not cosmetic. It influences splash, perceived rinse quality at low flow, noise, re-triggers, and maintenance frequency. Chicago Faucets touchless pages show multiple outlet options including pressure-compensating laminar outlets and non-aerating spray outlets in low flow ranges.

Table 2: Outlet selection guidance for common AEC conditions

| Condition | Typical problem | Outlet strategy to consider | Coordination note |

|---|---|---|---|

| Shallow basins, short reach | Splash and wet counters | Laminar or controlled stream | Fix geometry first if landing point is wrong |

| Ultra-low flow goals (0.35–0.5 gpm) | User dissatisfaction and re-triggers | Purpose-built low-flow outlet options, often spray-type | Validate with a mockup to avoid complaints |

| High-rise pressure variation | Inconsistent stream strength | Pressure-compensating outlets | Confirm stops and filters are accessible |

| Hard water regions | Clogging and drift | Serviceable outlet that is standardized | Build a cleaning and replacement plan |

Configuration and water hygiene: CF Connect as a facilities tool

Uneven use and low occupancy schedules raise water age and stagnation risk in low-use zones. CF Connect is explicit about hygiene flushing and repeatable settings: hygiene flush modes, longer pipe flush modes, adjustable duration and interval, presets, usage logs, and adjustable detection distance and safety shutoff.

Installation and serviceability: what the documents reveal

Reliability often comes down to practical steps: flushing supply lines, preventing debris from clogging inlets and mixing assemblies, and using documented troubleshooting logic for common symptoms like continuous run, no activation, and sensor window contamination.

Commissioning: how to spec “precision” so it shows up at turnover

Commissioning sequence that stays practical

- Pre-check basin geometry and water landing point near the drain centerline

- Confirm lighting and reflective surfaces do not produce false triggers

- Confirm stops, filters, and power are accessible

- Set detection distance to the smallest reliable activation zone

- Verify safety shutoff behavior is consistent across the restroom bank

- Verify outlet stream stability at actual building pressure

- Confirm adjacent faucets do not cross-trigger

- Only program hygiene flushing when justified, then document it and store presets

Specifier quick list: what to lock down in the project manual

- Model family and configuration, including what counts as an acceptable substitution

- Power type and access requirements

- Supply strategy: single tempered vs dual supply with mixer vs thermostatic option

- Outlet type and exact flow rate

- Compliance requirements: ASME/CSA, ADA where applicable, NSF/ANSI/CAN 61 and 372, ASSE 1070 where required, WaterSense where required

- Commissioning deliverable: final settings record and verified performance checklist

- O&M package: manuals, parts breakdowns, outlet maintenance interval

Category pages and technical references

Category pages requested

Chicago Faucets support documents and pages

Standards and water efficiency references

Location: Atlanta, GA

Profile: Interior designer with expertise in high-end hospitality and luxury residential washroom design. Known for creating cohesive aesthetic environments where aviation-style touchless faucets are focal design elements.